Imagine a 3D printing world where interruptions due to filament runout are a thing of the past. Welcome to the realm of the Creality Ender-7, a groundbreaking 3D printer that combines speed, precision, and versatility. With its high-speed printing capabilities, generous build volume, and compatibility with various filaments, the Ender-7 sets a new standard in the world of additive manufacturing.

And to complement its impressive features, the Creality Ender 7 Filament Sensor steps in as a crucial ally, ensuring seamless printing experiences by preventing filament shortages. Let’s dive deep into the world of the Ender-7 and its filament sensor to see how they can revolutionize your 3D printing journey.

The Creality Ender-7 is a filament-based 3D printer from Creality, known for its impressive features. Let’s dive into what makes it stand out:

High-Speed Printing: The Ender-7 boasts a normal printing speed of up to 250mm/s, allowing you to enjoy rapid printing while maintaining precise quality.

Build Volume: With a build volume of 220mm x 220mm x 300mm, it provides ample space for your creative projects.

Filament Compatibility: The Ender-7 is versatile and can work with a wide range of filaments, from standard PLA to more specialized materials.

Temperature Capabilities: It can reach a hot-end temperature of 260°C and a build plate temperature of 100°C, making it suitable for various filament types.

While the Ender-7 does not come with an integrated filament sensor, you can explore external options like the EZOut V3 Filament Sensor Kit or the Official Creality Filament Runout Sensor to enhance your printing experience. These sensors help prevent print failures due to filament depletion.

Let’s delve into the benefits of using a filament runout sensor in 3D printing. These sensors play a crucial role in enhancing the printing process. Here’s why they matter:

Avoiding Print Failures: Filament runout sensors detect when your printer runs out of filament. For smaller printers, this might not be critical, but for larger printers with substantial build areas, it’s essential. Imagine starting a lengthy print job only to realize halfway through that the filament spool is empty.

The sensor prevents such mishaps by pausing the print and allowing you to replace the filament.

Time and Material Savings: When a filament runout is detected, the printer stops, preventing wasted time and material. You won’t end up with incomplete or flawed prints due to filament depletion.

Large Print Jobs: For those ambitious projects that require more than a single spool of filament, the sensor becomes invaluable. Large prints often consume more than the standard 1kg spool. With a filament runout sensor, you can confidently tackle multi-spool prints without worrying about interruptions.

Smooth Continuation: Once you load a new spool and thread the filament through the extruder, the printer resumes from where it left off. No need to start over or manually adjust settings. It ensures a seamless continuation of your print job.

Compatibility Across Price Ranges: You don’t need an expensive printer to benefit from a filament runout sensor. Even budget-friendly models, like the Creality Sermoon D1, come equipped with this feature.

IMG Source: filamatrix.com

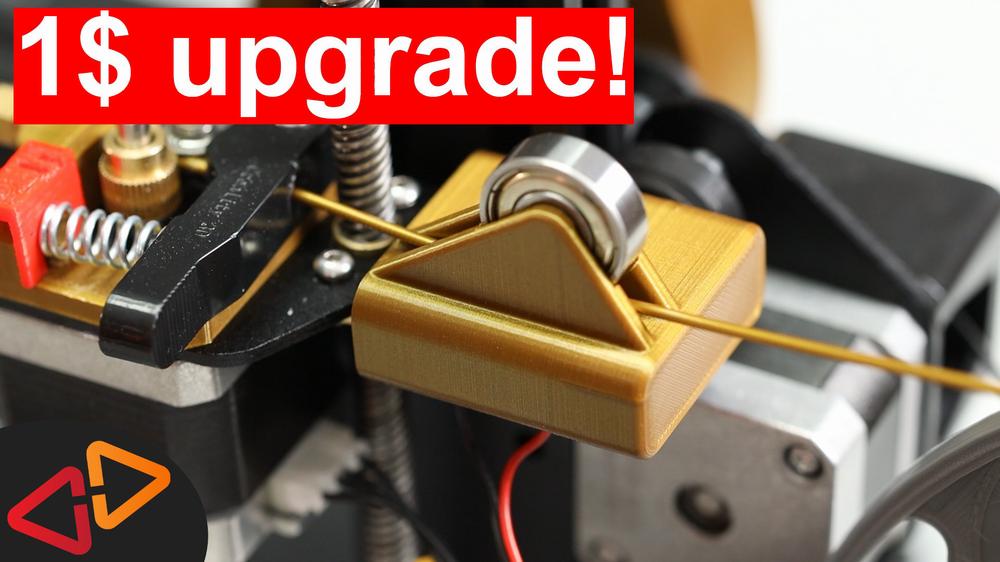

Let’s walk through the installation process for the Creality Ender 7 Filament Sensor. This handy sensor helps monitor your filament and prevents printing failures due to filament runout. Here are the steps to install it:

Prepare Your Tools and Materials:

Locate the Filament Sensor Position:

Mounting Height:

Mounting the Filament Sensor:

Print Settings:

Calibration and Testing:

Remember to consult your Ender-7 User Manual for additional details and safety precautions

IMG Source: crosslink.io

Proper maintenance of your Creality Ender 7 filament sensor is essential to ensure smooth 3D printing. Here are some effective tips for maintaining your filament sensor:

Filament Replacement:

Regular Cleaning and Lubrication:

IMG Source: media-amazon.com

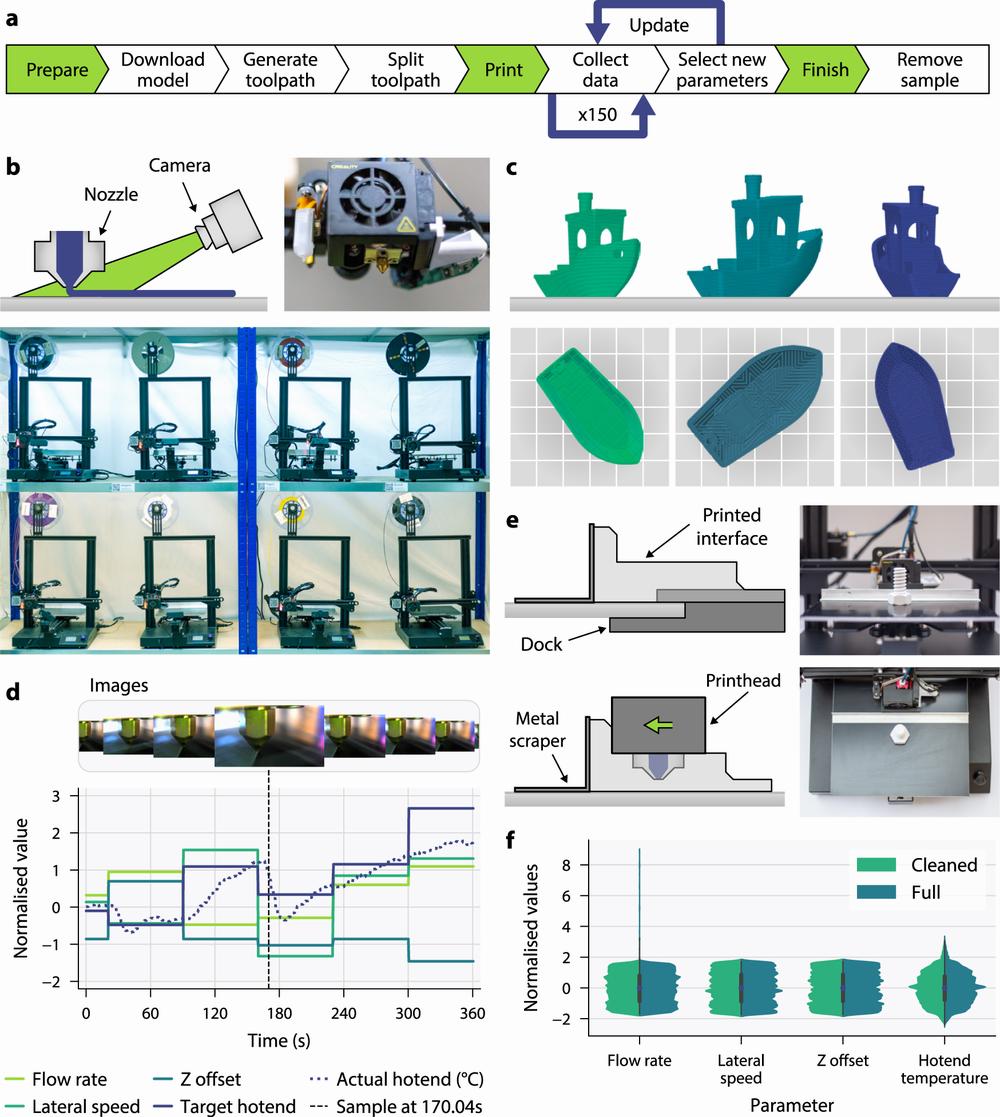

Let’s delve into how the Creality Ender-7 3D printer, with its impressive features, can enhance your 3D printing workflow.

High-Speed Printing:

Linear Rails for Stability:

Cooling Efficiency and Nozzle Design:

Versatility in Filament Compatibility:

Specifications:

Price and Availability:

IMG Source: springernature.com

By following proper installation steps and maintenance tips, you can maximize the performance and longevity of your Ender-7 filament sensor. Embrace the future of 3D printing with the Creality Ender-7 and its essential filament sensor, and unlock a world of endless creative possibilities.