Are you looking to enhance your 3D printing experience with the Creality CR-10 Filament Sensor? This crucial component can make a significant difference in the success of your prints. From filament monitoring to pause functionality, the filament sensor ensures that your printer operates smoothly without wastage.

Let’s explore the key benefits and installation process to understand how the CR-10 filament sensor can elevate your 3D printing projects.

The Creality CR-10 filament sensor is a crucial component of the 3D printer. Its primary function is to ensure that the printer always uses the correct amount of filament during printing. Here are some key points about the CR-10 filament sensor:

Filament Monitoring: The sensor continuously monitors the filament as it feeds into the printer. If the filament runs out completely, the sensor can trigger an action, such as pausing the print job. This prevents the print from being ruined due to insufficient filament.

Pause Functionality: When the filament sensor detects that the spool is empty or nearing the end, it can pause the print process. This gives you an opportunity to replace the filament spool before continuing the print job.

Installation: Installing a filament runout sensor on your Creality CR-10 involves configuring the hardware and adjusting settings in the Marlin firmware. You’ll need to connect the sensor to the appropriate pins on the control board and configure the firmware to recognize the sensor.

Benefits: The filament sensor provides peace of mind during long prints, especially when using large spools of filament. It helps prevent wasted time and material by avoiding incomplete prints due to filament depletion.

If you’re interested in adding a filament sensor to your CR-10, there are various resources available online, including tutorials and guides. You can find detailed instructions on how to install and configure the sensor to enhance your 3D printing experience.

Let’s delve into the benefits of filament sensors in 3D printers.

Filament Runout Detection:

Cost and Time Savings:

Ease of Use:

Compatibility:

In summary, filament sensors are a practical feature that can save you time, money, and frustration, especially when working with large prints. Whether you’re a seasoned 3D printing enthusiast or a beginner, having a filament sensor can significantly improve your printing experience.

IMG Source: circuitdigest.com

Let’s walk through the installation process for a Filament Runout Sensor on your Creality CR-10 3D printer. This sensor helps prevent print failures by detecting when your filament runs out during a print job. Here are the steps:

Hardware Configuration:

Marlin Configuration:

Configuration.h file.#define FILAMENT_RUNOUT_SENSOR

#define FILAMENT_RUNOUT_SENSOR_INVERTING true // Adjust if needed

Conclusion:

For visual guidance, you can also refer to this YouTube video by Chris Riley, where he demonstrates the installation process

IMG Source: cults3d.com

If you’re experiencing issues with your filament sensor, here are some troubleshooting tips to help you get back on track:

Check Firmware Compatibility:

Ensure that you have the correct firmware version for your specific filament sensor. The new IR Filament Sensor requires the S/S+ version of the firmware. Having the incorrect firmware might cause calibration failures due to differences in extruder part designs.

Verify Wiring Orientation:

Confirm that the connector is properly oriented. It should be on the bottom row of pins, covering all pins, with the red wire on the right. Refer to the picture below for the correct orientation.

!Wiring Orientation

Check Extruder Assembly:

Before disassembling anything, inspect key parts of your extruder assembly:

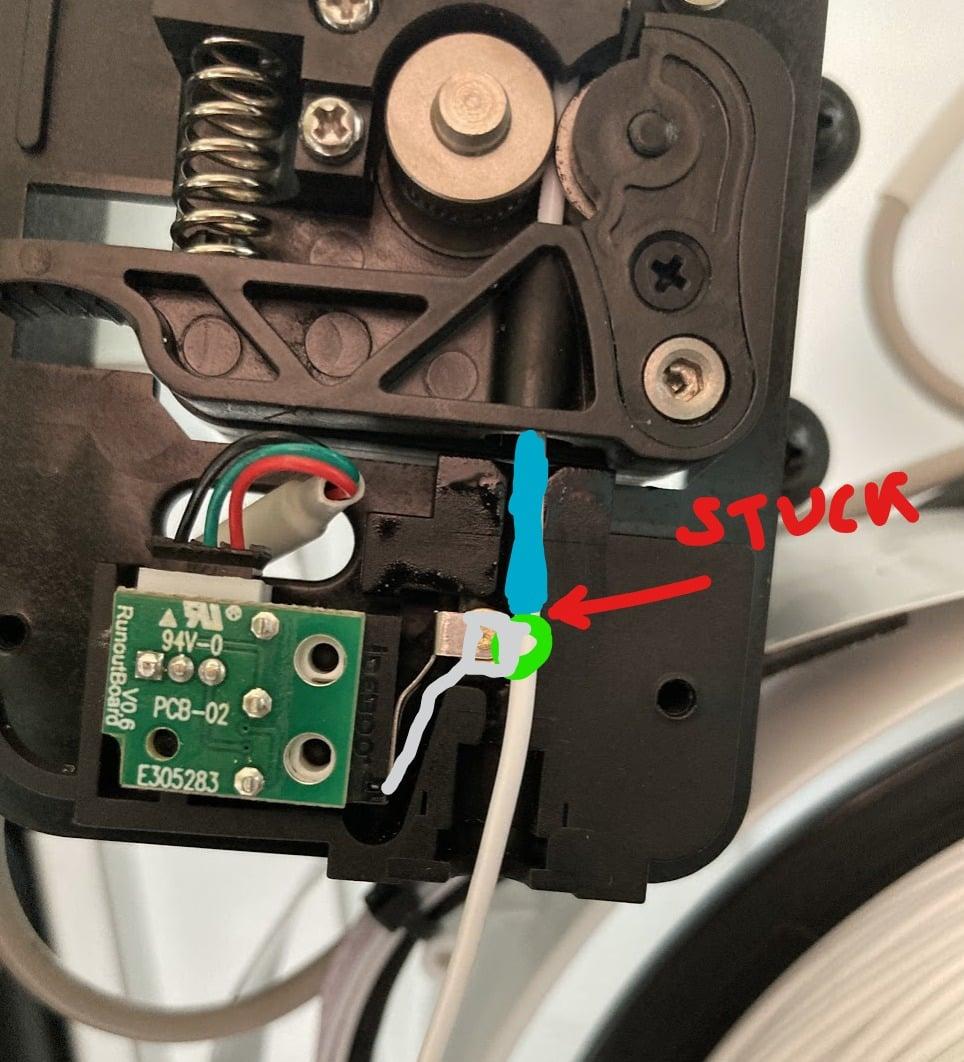

Access the Filament Sensor Mechanism:

IMG Source: redd.it

Maintaining the Creality CR-10 Filament Sensor is essential to ensure smooth 3D printing. Here are some tips to keep it in good working condition:

Calibration Check:

Cleaning:

Trigger Adjustment:

Filament Replacement:

IMG Source: ytimg.com

By following the installation steps and troubleshooting tips, you can optimize the performance of your CR-10 and enjoy uninterrupted 3D printing. Embrace the efficiency and reliability that the Creality CR-10 Filament Sensor brings to your printing projects.