The Bambu Lab X1 Bowden Tube is a critical component in the operation of Bambu Lab X1 and X1 Carbon 3D printers, responsible for guiding filament from the extruder to the print head. Understanding the specifications and purpose of this PTFE tube is essential for ensuring optimal printing performance. In this article, we will delve into the details of the Bowden tube used in Bambu Lab printers and explore maintenance tips and troubleshooting techniques to help you prolong its lifespan and enhance your overall printing experience.

The Bambu Lab X1 and X1 Carbon 3D printers utilize a PTFE (polytetrafluoroethylene) bowden tube to guide filament from the extruder to the print head. This tube plays a crucial role in ensuring smooth filament flow during printing. However, over time, the tube can experience wear and tear due to movement and pressure.

Here are some relevant details about the bowden tube used in Bambu Lab printers:

PTFE Tube Specifications:

Purpose of the PTFE Tube:

Challenges:

To address this issue, some users have designed reinforcements or strain relief for the bowden tube. These add-ons provide extra support where the tube enters the print head, helping to prolong its lifespan. If you’re experiencing any issues with your bowden tube, consider exploring these reinforcement solutions.

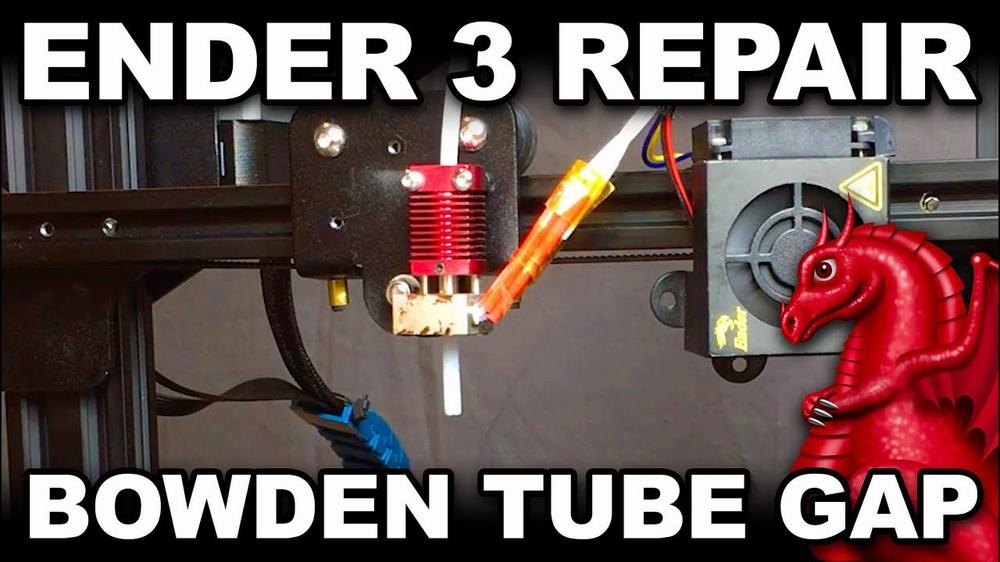

Installing a Bowden tube on a 3D printer is an essential step, especially for beginners. The Bowden tube connects the extruder (where the filament is pushed) to the hot end nozzle (where the filament is melted and deposited). Here are the steps to install a Bowden tube:

Switch off and unplug the printer: Safety first! Make sure your 3D printer is turned off and unplugged before you start any maintenance.

Disconnect the Bowden tube from the 3D printer: Locate the end of the Bowden tube where it connects to the extruder. Gently release any clips or fittings holding it in place and remove it.

Clean the Bowden tube with isopropyl alcohol: Use a lint-free cloth or cotton swab soaked in isopropyl alcohol to clean the inside and outside of the Bowden tube. This ensures there’s no residue or dirt that could affect filament flow.

Insert the Bowden tube into the connector: At the hot end (where the nozzle is), find the other end of the Bowden tube. Insert it into the connector, making sure it goes all the way in. Some printers have a collet clip that you need to pull back while inserting the tube.

Tighten the connector: Secure the Bowden tube by tightening the connector. If your printer has a collet clip, release it to lock the tube in place.

Plug the 3D printer into the power socket: Once the Bowden tube is securely attached, plug your printer back in and turn it on.

Test the connection: Load some filament and perform a test print. Make sure the filament flows smoothly through the Bowden tube without any blockages or kinks.

For visual guidance, you can also check out tutorials on platforms like YouTube, where experienced users demonstrate the process . Additionally, if you’re using a specific type of Bowden tube (such as the Capricorn PTFE tube), follow the manufacturer’s instructions for optimal results .

IMG Source: ytimg.com

Proper maintenance of your Bambu Lab X1 3D printer is essential to keep it running smoothly. Here are some maintenance tips to ensure optimal performance:

Lubricate the Bowden Tube: Regularly apply Super Lube Synthetic PTFE Lube to the Bowden tube. This helps reduce friction and ensures smooth filament movement during printing.

Clean the Hotend and Nozzle: Use 99% isopropyl alcohol to clean the hotend and nozzle. This removes any residue or clogs that might affect print quality.

Inspect the PTFE Tube: Check the PTFE tube (Bowden tube) for wear or damage. If you notice any issues, replace it promptly.

Desiccant Maintenance: Keep your filament dry by using rechargeable desiccant packs. Check them regularly and recharge or replace as needed.

Remove Debris: Use a canned air duster to remove any dust or debris from the printer components, including the extruder and hotend.

Check for Loose Connections: Inspect all connections, wires, and screws. Tighten any loose parts to prevent issues during printing.

Calibrate the Bed: Regularly calibrate the print bed to ensure proper adhesion and layer consistency.

Monitor Humidity: With the new humidity sensor feature, check the desiccant when it shows yellow. This helps maintain optimal filament conditions.

IMG Source: redd.it

The Bambu Lab X1 and X1 Carbon 3D printers utilize a PTFE (polytetrafluoroethylene) Bowden tube to guide filament from the spool to the print head. However, over time, there can be issues related to the tube. Here are some troubleshooting techniques:

Tube Reinforcement / Strain Relief:

Check Tube Connections:

Inspect Tube Coupler and Clips:

Filament Path Alignment:

Temperature Considerations:

Regular Maintenance:

Remember that proper maintenance and attention to the PTFE tube can significantly improve the performance and reliability of your Bambu Lab X1 printer.

IMG Source: redd.it

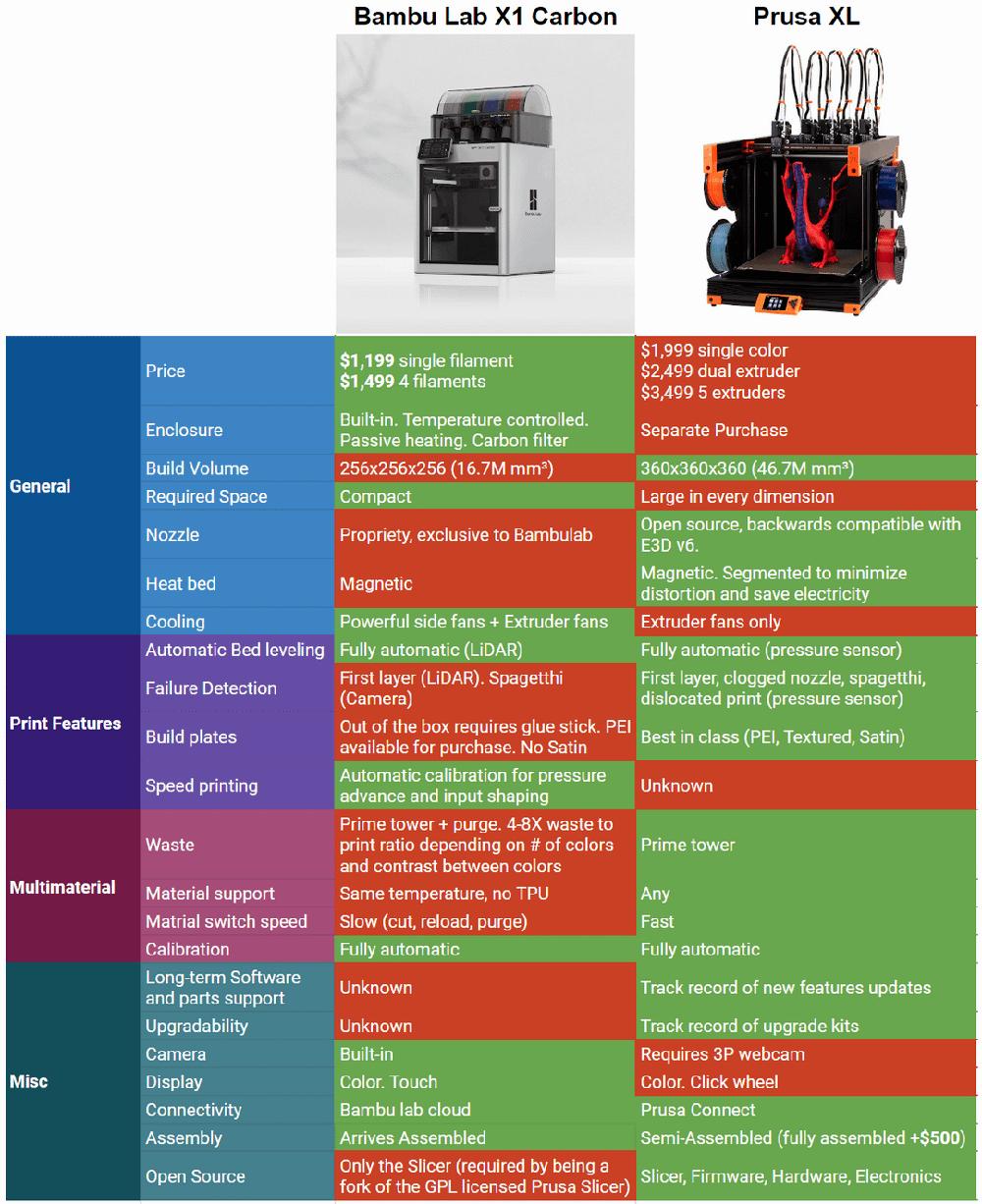

Let’s explore the advantages of the Bambu Lab X1 Carbon Bowden Tube compared to its competitors:

Advanced Material Compatibility:

Support Material Management:

Speed and Quality:

Build Volume:

User Experience:

Remember that choosing a 3D printer depends on your specific needs and preferences. Other competitors, such as Creality’s K1 and Qidi-Tech’s X-Smart 3, offer alternatives at different price points while maintaining similar performance

IMG Source: redd.it

Remember, regular care and attention to the Bowden tube will go a long way in maximizing the longevity and efficiency of your Bambu Lab X1 printer. Embrace these tips to enhance your 3D printing experience and unleash the full potential of your machine.