Are you looking to optimize the performance of your Creality K1C 3D printer by enhancing its cooling system? The efficient operation of cooling fans is essential for maintaining print quality and preventing overheating. Let’s delve into the world of Creality K1C cooling fans to discover how they contribute to your printing experience and explore some useful tips for fan installation and maintenance.

The Creality K1C 3D printer features several cooling fans to maintain optimal printing conditions. Let’s explore the fan setup:

Side Cooling Fan: The K1C has a side cooling fan. However, it seems to be causing issues with Silk filament, resulting in support failures on the fan side. If you’re primarily printing with regular PLA, you can consider adjusting the temperature and potentially removing the fan altogether. Keep in mind that this fan can be quite loud.

Housing Fan: The printer also includes a housing fan. Unfortunately, I don’t have specific details about its purpose or location, but it likely contributes to overall cooling and ventilation.

Print Head Fan: The print head features its own fan (referred to as P0). This fan plays a crucial role in cooling the printed layers during the printing process.

Remember that balancing cooling and warping is essential, especially for larger build volumes like the K1C. If you’re experiencing excessive noise from the fans, consider adjusting their speeds or exploring alternative profiles to find a balance that works for your printing needs

Let’s explore the different types of cooling fans commonly used in 3D printers:

Hot-End Fan: This fan is positioned near the hot end (extruder) of the printer. Its primary purpose is to cool the heat sink attached to the hot end. By dissipating excess heat, it ensures consistent filament flow and prevents clogs.

The hot-end fan is crucial for maintaining print quality and preventing filament jams .

Part Cooling Fan (Layer Fan): The part cooling fan is responsible for cooling the printed layers as they are deposited. It helps solidify the material quickly, reducing warping and improving overall print quality. This fan blows air directly onto the printed object during the printing process .

Control Board Fan: Located on the printer’s control board, this fan prevents overheating. It ensures stable operation by dissipating heat generated by the electronics components. Without proper cooling, the control board could malfunction or even fail .

Power Supply Fan: The power supply unit (PSU) fan keeps the power supply cool during long printing sessions. It’s essential for preventing overheating and ensuring safe operation .

Enclosure Fan (Chamber Fan): Some 3D printers have enclosures to maintain a stable printing environment. The enclosure fan regulates the temperature inside the chamber. It helps prevent temperature fluctuations that could affect print quality .

Radial Fans (Axial Fans): These fans have blades that rotate around an axis, moving air parallel to the rotation axis. Radial fans are commonly used in desktop 3D printers for part cooling. They efficiently direct airflow onto the printed layers .

Blower Fans: Blower fans, also known as centrifugal fans, have a different design. They draw air in from the sides and expel it radially. Blower fans are often used for cooling the hot end and electronics components.

They provide more focused airflow but may be noisier than radial fans .

IMG Source: all3dp.com

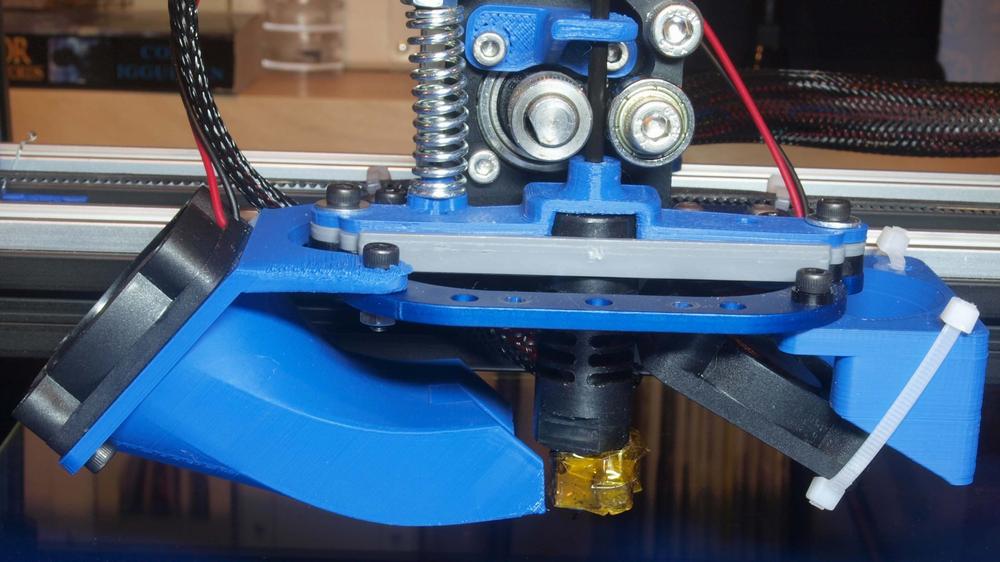

Here’s a brief guide on installing cooling fans for your Creality K1C 3D printer:

Understanding the Printer:

Fan System Overview:

Installation Steps:

Remember to consult the official Creality K1C User Manual

For more advanced modifications or troubleshooting, you can explore the Creality K1 Series Wiki on GitHub.

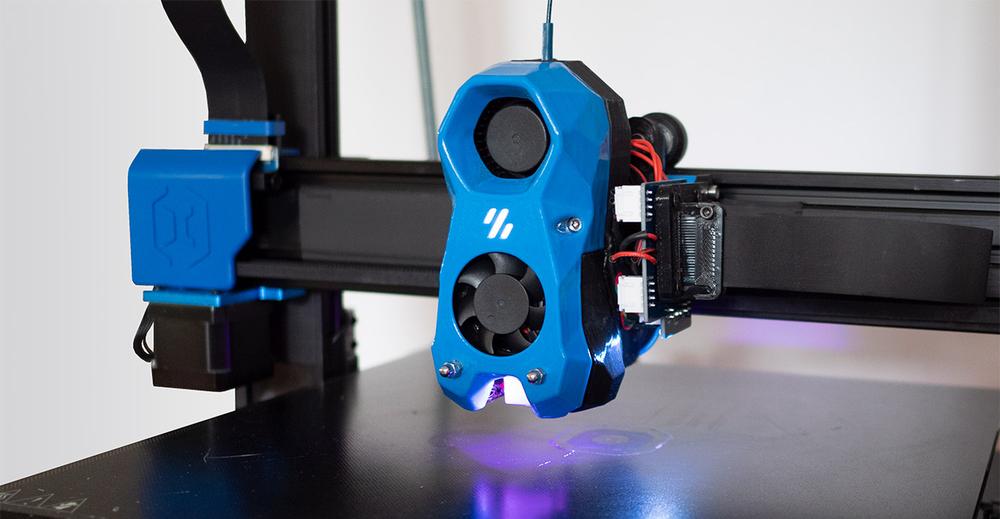

IMG Source: cults3d.com

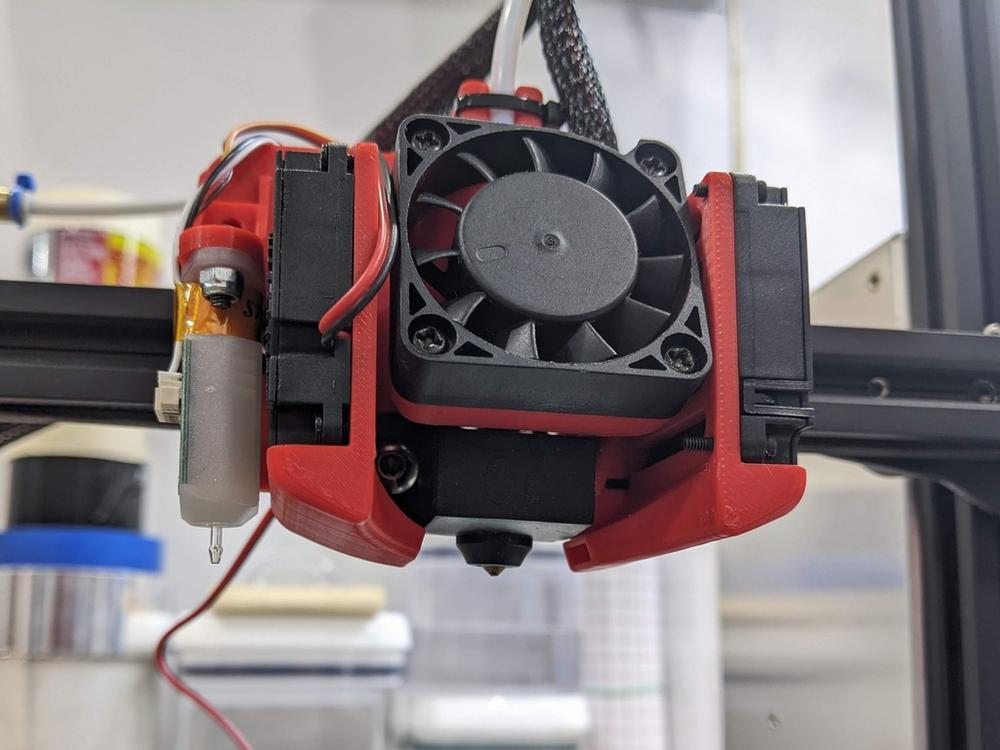

Properly maintaining your cooling fans is essential for optimal performance and longevity. Here are some tips to keep your fans running smoothly:

Choose the Right Fans:

Monitor Temperatures:

Regularly Clean Your Fans:

Avoid Obstructing Airflow:

Fan Placement:

Invest in Proper Wiring and Relays:

Remember, maintaining cooling fans is essential for efficient operation and preventing overheating. Regular cleaning and proper placement will help keep your system cool and running smoothly.

IMG Source: voltapc.sg

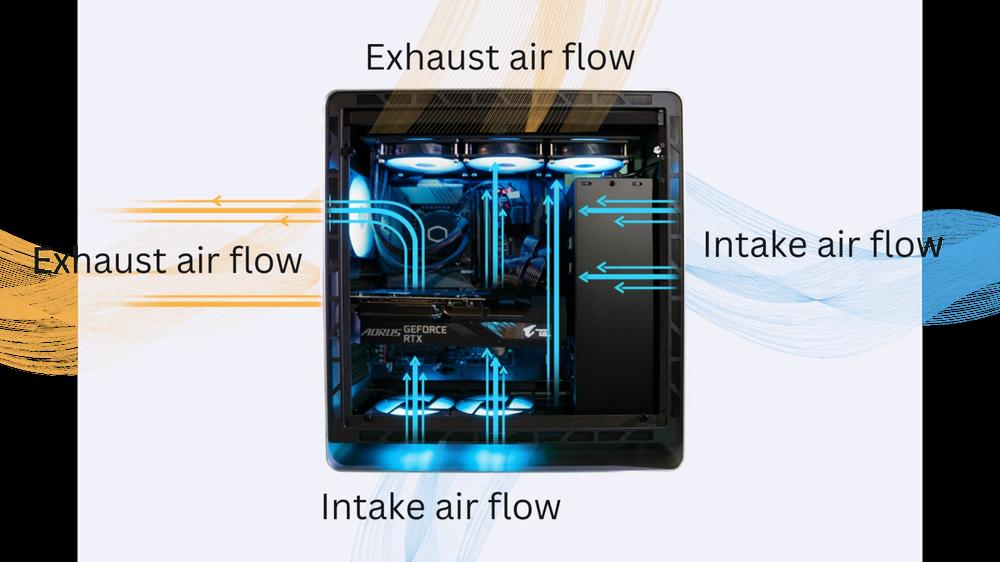

Improving your 3D printing experience through fan upgrades is a smart move. Let’s dive into the details:

Cooling Fans and Print Quality:

Your slicer usually starts the cooling fan after the initial layers to ensure proper adhesion to the build surface.

Ender 3 Fan Upgrades:

Advanced Upgrades:

IMG Source: 3dpblog.com

Incorporating fan upgrades and following best practices for fan installation and maintenance will help you elevate your 3D printing experience with the Creality K1C cooling fans.