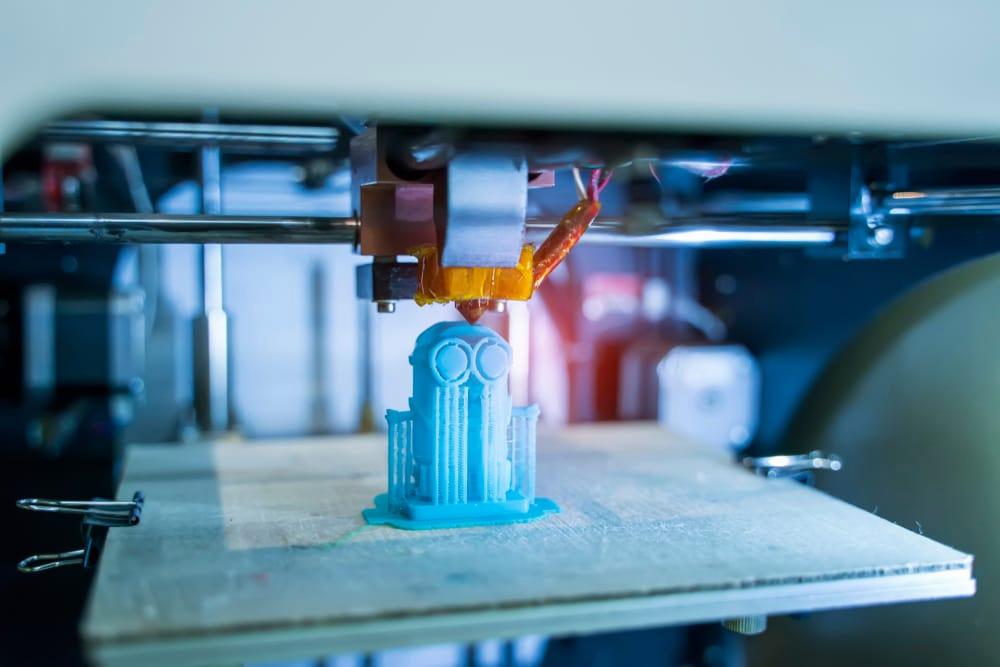

Are you struggling to figure out how to remove supports from your 3D prints without damaging the final product? Look no further! In this comprehensive guide, we’ll walk you through the essential steps and techniques to safely and effectively eliminate supports from your 3D prints.

Whether you’re a beginner or an experienced enthusiast, mastering the art of support removal is crucial for achieving flawless results. So, let’s dive in and explore the best practices for removing supports from your 3D prints.

Removing supports from a 3D print can be done carefully to avoid damaging the print. Here are some general steps to follow:

Adjust Settings: If possible, adjust your 3D printer settings to make supports easier to remove. This includes increasing the Z distance between the support and the print, and using a support interface layer with a different pattern direction.

Orient the Model: Try to orient the model in a way that minimizes the need for supports.

Use Tools: Employ tools like clippers, metal spatula, metal hooks, or a wood burning tool to carefully remove the supports. Always wear safety glasses and a respirator when working with plastic to protect yourself.

Go Slow: Take your time and be patient. Rushing the process can damage the model or the fine details.

Post-Processing: After removing the supports, you may need to sand the areas to smooth out any imperfections. Remember, the best method may vary depending on your specific 3D printing project, so it’s always good to refer to the manual or guidelines provided with your 3D printer for the best results .

3D printing support structures play a crucial role in successfully creating intricate 3D models. Let’s delve into the basics and techniques for using supports effectively:

What are 3D Print Support Structures?

Do 3D Prints Always Require Supports?

Automatic vs. Custom Supports:

Common Issues with Supports:

Advanced Techniques:

For more detailed instructions, check out this comprehensive guide

IMG Source: materialise.com

When it comes to removing 3D print supports, having the right tools can make the process much easier and more efficient. Here are some of the best tools you can use:

Flush Cutter: A flush cutter is a small, sharp tool that allows you to snip off supports close to the model. It’s especially useful for removing smaller sections of support material without damaging your print.

Tweezers: A good pair of tweezers helps you grab and remove tiny support remnants. Look for tweezers with fine tips for precision.

Needle-Nose Pliers: Needle-nose pliers are handy for gripping and twisting larger support sections. They provide better leverage for removing stubborn supports.

X-acto Knife: An X-acto knife with extra blades is great for carefully cutting away supports. Be cautious not to damage the model while doing so.

Small Files: Use a filing tool to manage rough edges left by supports. Rub the file against stubborn pieces of material to smooth them out.

High Grit Sandpaper: Sandpaper with a high grit (fine texture) can help you smooth any remaining rough spots after removing supports.

Remember to analyze your model after printing to identify support locations. Start by removing smaller sections first, as they are weaker and easier to clear. Then tackle the larger, harder-to-remove sections with care

IMG Source: wp.com

When it comes to safely removing supports from 3D printed objects, there are several methods you can employ. Let’s explore some effective techniques:

Break Supports Off:

Clip Supports Off:

Use a Knife:

Post-Processing:

Additionally, if you’ve used dissolvable supports (such as PVA or HIPS), you can soak your print in water or limonene to remove them

IMG Source: amazonaws.com

To achieve a polished finish on your 3D printed objects, there are several techniques you can employ. Let’s explore some of them:

Sanding & Polishing:

Polishing compounds or pastes can further enhance the finish.

Apply Primer & Fill Gaps/Seams:

Painting:

Adjust Slicer Settings:

Epoxy Coating:

Acetone Vapor Smoothing:

Replace the Nozzle:

Tighten Hotend Assembly & Belts:

Print Model Face Down:

Fix Vibrations around the 3D Printer:

Try Printing with Matte Filament:

Metal Plating (Electroplating):

IMG Source: 3dnatives.com

So, go ahead and put your newfound knowledge into practice, and watch as your 3D prints truly come to life without a trace of those pesky supports in sight!