Welcome to the fascinating realm of Creality K1C stepper motors! If you’re curious about the intricate components driving the precision of your 3D printer, you’re in the right place. Discover the inner workings of these motors, their unique specifications, and how they play a crucial role in your printing experience.

The Creality K1C 3D printer utilizes circular stepper motors specifically designed for its operation. Let’s delve into the details:

Motor Specifications:

Tuning X-Y Motors:

Let’s delve into the fascinating world of stepper motors and their crucial role in 3D printing. Stepper motors are essential components in 3D printers, enabling precise control over movement. Here’s a comprehensive overview to help you understand and choose the right stepper motor for your 3D printing needs.

A stepper motor is an electric motor that rotates in discrete steps. Unlike conventional motors that rotate continuously, stepper motors move in precise increments due to the sequential activation of electromagnetic coils. This unique property makes them ideal for applications like 3D printing, where precise positioning is crucial.

The stepper driver acts as the brain of the stepper motor, determining its performance parameters. Let’s explore different types:

Bi-Level Stepper Driver: This type allows current flow in both directions through each coil phase. It’s commonly used in 3D printers.

L/R Stepper Driver: These drivers control the direction and sequence of current flow in the coils, precisely controlling motor rotation.

Chopper Stepper Driver (PWM) or Microstep: These drivers use pulse-width modulation (PWM) to achieve smoother motion by dividing each step into smaller microsteps. They enhance precision and reduce noise.

When selecting a stepper motor, keep these factors in mind:

Step Count: The number of steps per revolution affects precision. Higher step counts result in finer movement.

Motor Size: Consider the physical dimensions of the motor to ensure it fits your printer’s design.

Torque Rating: Torque determines the motor’s ability to move the printer’s components. Higher torque is beneficial for larger printers or heavy loads.

Number of Windings: More windings generally lead to better performance, but it’s essential to balance this with power consumption.

The NEMA Standard: NEMA (National Electrical Manufacturers Association) defines motor sizes. Common NEMA sizes for 3D printers are NEMA 17 and NEMA 23.

While both have their merits, stepper motors are more common in 3D printers. Steppers offer sufficient accuracy for most consumer-level applications, making them popular among hobbyists and professionals alike.

IMG Source: all3dp.com

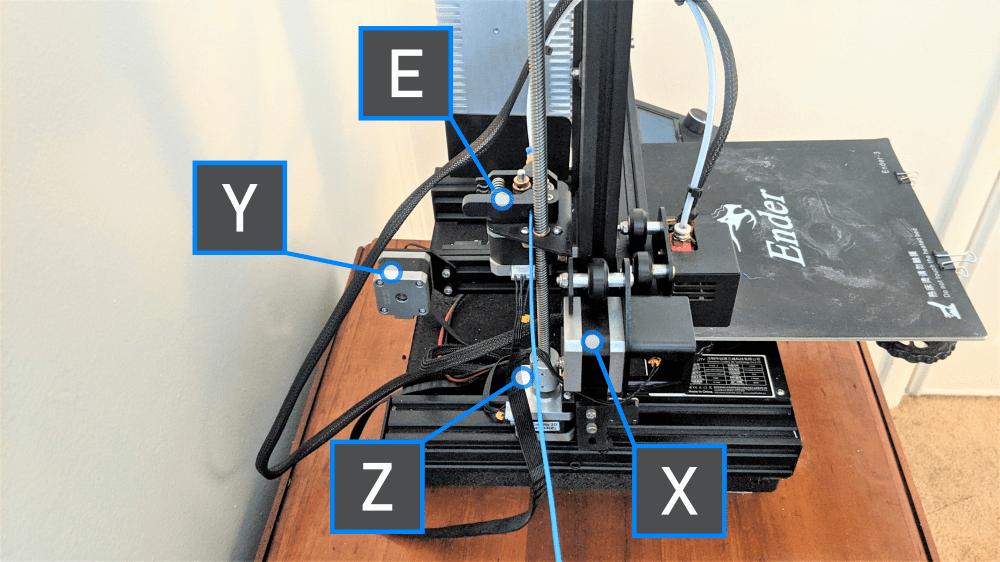

Calibrating the stepper motors of your Creality K1C 3D printer is essential to ensure accurate movement in all three axes (X, Y, and Z). Proper calibration ensures that the nozzle moves precisely as expected by the slicer, resulting in accurate dimensions for your printed parts. Let’s walk through the steps for calibrating each axis:

Attach a Ruler to the Axis:

Calibrate the X-Axis:

Repeat for the Y-Axis:

Calibrate the Z-Axis:

Check the Calibration:

For more detailed information on other essential calibrations, check out this comprehensive guide: 3D Printer Calibration: Step-by-Step to Perfect Results.

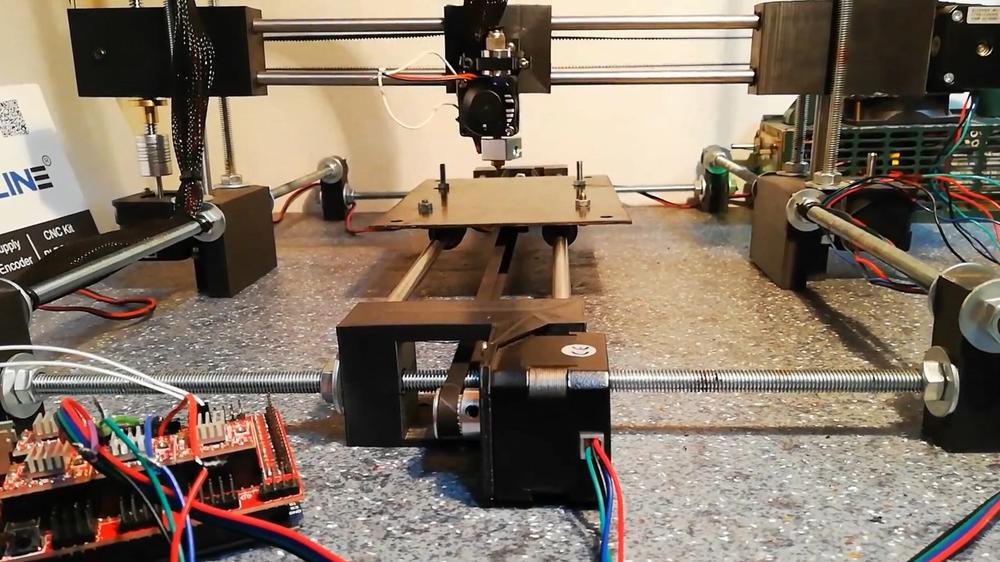

IMG Source: wp.com

Troubleshooting stepper motor issues on your Creality K1C 3D printer can be a bit tricky, but I’ll provide some guidance based on available information. Remember to follow safety precautions and turn off the printer before attempting any adjustments or replacements.

Check Wiring and Connections:

Motor Replacement:

Motor Dampeners:

Custom Gantry Upgrade:

IMG Source: ytimg.com

Let’s explore the advantages of the Creality K1C 3D printer:

High Speed Printing: The Creality K1C is a speed champion, capable of achieving printing speeds of up to 600mm/s. This rapid printing capability allows you to create your 3D models efficiently and save valuable time.

Carbon Fiber Compatibility: The K1C excels in carbon fiber prints, making it an excellent choice for hobbyists and professionals alike. Its robust extrusion system ensures reliable filament feeding, even with challenging materials.

Open-Source Hardware and Software: Both the hardware and software of the K1C are open-source. This means you have the freedom to customize and modify the printer to suit your specific needs. The Creality OS, based on Klipper, enables advanced functions like linear advance, giving you more control over your prints.

Smart Cooling and Retraction: The Creality Print slicer features smart cooling, optimal retraction settings, and slim tree supports. These features contribute to better print quality and reduce the risk of issues like stringing and warping.

Optional Accessories: The K1C offers a variety of quality optional accessories, allowing you to enhance your printing experience. Whether it’s upgrading components or adding features, you have the flexibility to tailor the printer to your liking.

IMG Source: media-amazon.com

Dive deeper into the world of stepper motors, experiment with calibrations, and explore innovative solutions to maximize the potential of your 3D printing endeavors. Embrace the precision and reliability of Creality K1C stepper motors for unparalleled creativity and craftsmanship in your printing projects.