Are you looking to enhance the performance of your Creality K1C 3D printer? Dive into the world of Creality K1C pulleys and discover how these essential components can elevate your printing experience to a whole new level. From installation tips to maintenance guidelines, this article will provide you with detailed insights into optimizing your printer’s pulley system for improved reliability and efficiency.

The Creality K1C is an intriguing 3D printer model that has garnered attention. Let’s delve into some details about it:

Features and Upgrades:

Mechanical Properties and Durability:

Pulley Replacement:

The Creality K1C 3D printer boasts several advantages over its predecessor, the Creality K1. Let’s delve into the benefits of the K1C:

Reliable Extrusion: The K1C features an all-metal extruder, designed to withstand the wear and tear associated with carbon fiber filaments. This robust extruder ensures consistent and reliable filament feeding during printing.

Quick-Swap Tri-Metal Nozzle: Unlike the K1’s standard brass nozzle, the K1C comes equipped with a proprietary “unicorn tri-metal” nozzle. This specialized nozzle offers improved thermal conductivity, wear resistance, and heat break performance, enhancing overall print quality.

High Printing Speed: The K1C can achieve a maximum printing speed of 600mm/s, allowing for faster and more efficient printing.

Carbon Fiber Filament Support: The K1C is optimized for carbon fiber filaments, making it an excellent choice for projects that require the strength and durability of these materials.

Intelligent AI Camera: The K1C features an integrated AI camera, acting as your visual guide during printing. This smart feature enhances monitoring and allows you to keep an eye on your prints remotely.

Wider Applications: With its carbon fiber printing capabilities, the K1C opens up new possibilities for reinvented and sturdier 3D prints.

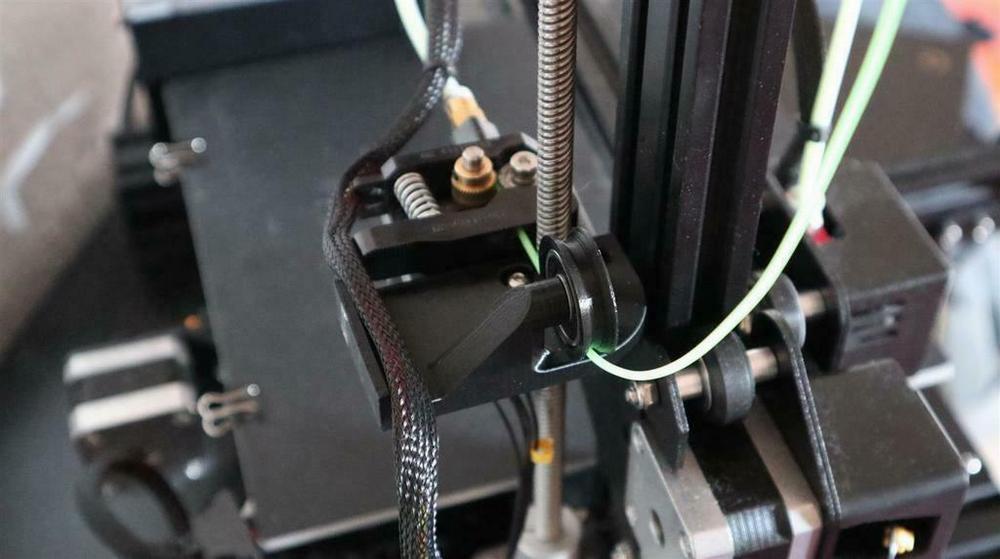

IMG Source: redd.it

Let’s walk through the installation process for the Creality K1C printer’s pulleys. Proper installation ensures smooth operation and accurate printing. Here are the steps:

Unboxing and Preparation:

Access the Printer Interior:

Remove the Top Metal Frame (Without Detaching the Gantry):

Remove the Motors:

Replace the Pulleys:

Reassemble Everything:

Adjust the Belt Tension:

Remember to consult the official Creality K1C user manual for detailed instructions and illustrations

IMG Source: cults3d.com

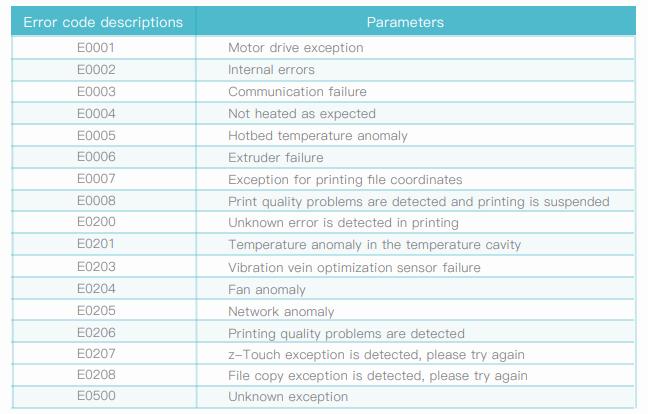

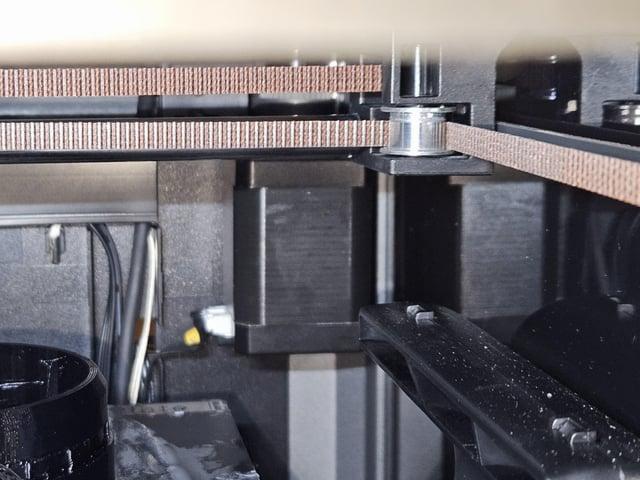

Proper maintenance of the pulleys in your Creality K1C 3D printer is essential for optimal performance. Here are some guidelines to help you maintain the pulleys:

Regular Inspection:

Cleaning:

Lubrication:

Tension Adjustment:

Alignment:

Belt Condition:

Remember to consult the official user manual for your Creality K1C printer for specific instructions and safety precautions

IMG Source: creality.com

The Creality K1C is a 3D printer that builds upon its predecessor, the K1, with several notable upgrades. Let’s dive into the details:

Upgraded Nozzle: The K1C features a hardened steel nozzle designed to withstand temperatures of up to 300°C. This improvement allows it to reliably print abrasive carbon-fiber-infused filaments like PLA-CF and PETG-CF, as well as high-temperature materials such as ASA and PC.

All-Metal Direct-Drive Extruder: The K1C boasts an all-metal direct-drive extruder that provides better filament feeding reliability compared to the original K1. This enhancement ensures smoother filament flow into the hotend.

Built-In Camera: The printer comes equipped with an AI camera, allowing you to monitor your prints remotely. This feature is handy for keeping an eye on your project’s progress without being physically present.

Print Quality: The K1C delivers impressive print quality, making it suitable for both beginners and experienced users. Even when printing at faster speeds, it consistently produces great results.

However, there are a few limitations to consider:

Single Color Printing: The K1C supports single-color printing only. If you’re looking for multi-color capabilities, this might not be the right choice.

Noise Level: Some users find the K1C to be noisy during operation. Keep this in mind if noise is a concern in your workspace.

Filament Change Process: Changing filament on the K1C can be a bit frustrating due to the design of the hot end and nozzle replacement process.

In summary, the Creality K1C offers a shallow learning curve for newcomers, reliable performance, and compatibility with a wide variety of filaments. If you’re in the market for a 3D printer, the K1C is definitely worth considering.

IMG Source: redd.it