Are you looking to enhance the performance of your Creality Ender 7 3D printer through optimized belt maintenance and upgrades? Dive into the world of Creality Ender 7 belts to discover essential information on belt specifications, replacement procedures, firmware updates, and more. Understanding the intricacies of your printer’s belts is crucial for ensuring smooth operation and high-quality prints.

The Creality Ender-7 is a remarkable 3D printer, and understanding its components is essential for maintenance and upgrades. Let’s delve into the details about the belts for the Ender-7:

Belt Specifications:

Belt Replacement:

Firmware and Software:

The Creality Ender 7 is a fast 3D printer that promises to deliver prints at breakneck speeds. When it comes to belts, here’s what you need to know:

Belt Kit: If you’re looking for replacement belts, Creality offers a Belt Kit that includes belts suitable for various 3D printers. These belts are 2GT W6 type and come in different lengths. You can cut them to the required size and attach copper bushings to both ends.

Keep a 1-2mm clearance between the copper bushing and the belt connector. Here are some compatible models and their respective belt specifications:

Remember that the length of the belt must correspond to the specified parameters, with a tolerance of +1.5mm. Ensure the cross-section is flat for optimal performance.

Copper Bushings: If you need copper bushings separately, you can check with the manufacturer or authorized suppliers to see if they offer them as standalone components.

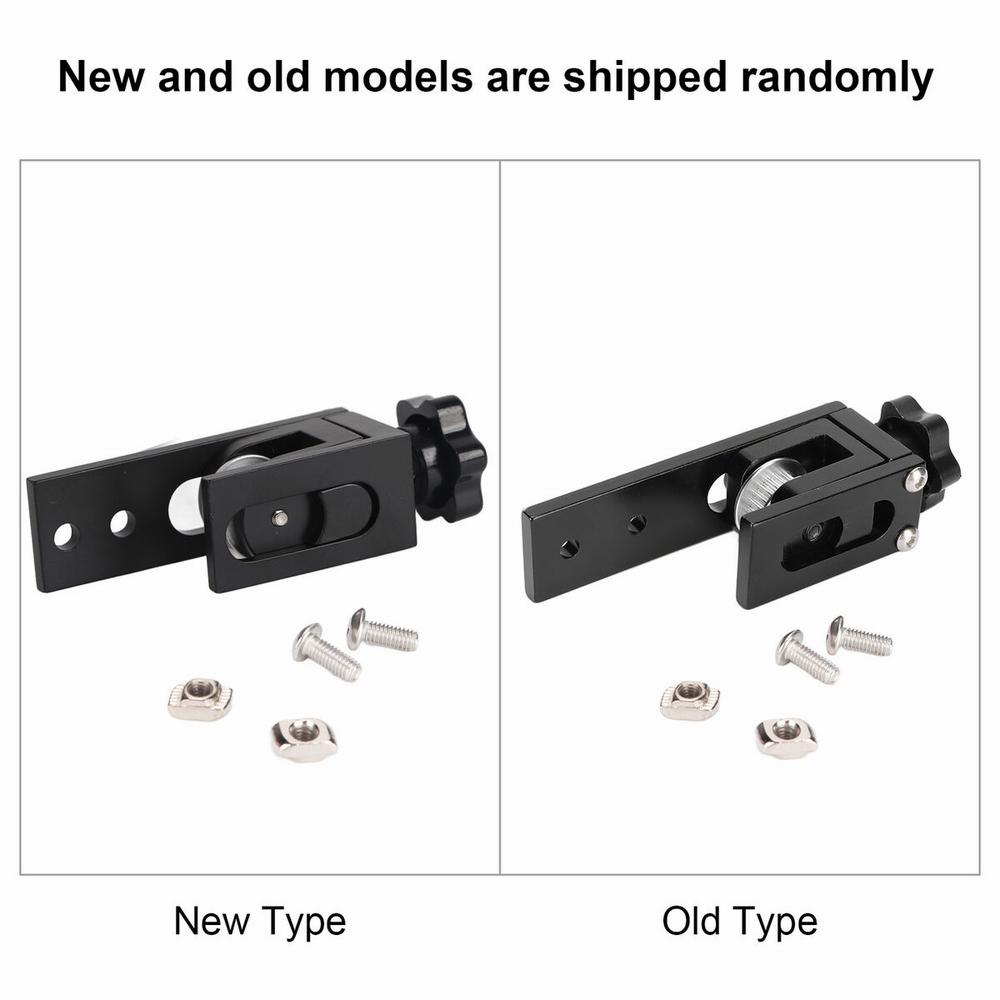

IMG Source: ebayimg.com

Proper belt maintenance is crucial for keeping your Creality Ender 7 3D printer in optimal condition. Regular care ensures smooth operation and accurate prints. Here are some steps you can follow for Y-axis synchronous belt replacement:

Inspect the Belt:

Loosen the Tension:

Remove the Old Belt:

Install the New Belt:

Tension Adjustment:

Check Alignment:

Test Print:

Remember to consult your printer’s manual or official Creality resources for specific instructions related to your Ender 7 model. Regular maintenance, including belt care, will help prolong the life of your printer and improve print quality.

IMG Source: ebayimg.com

Proper care of the belts in your Ender 7 3D printer is essential for maintaining print quality and preventing issues. Here are some tips to keep your belts in good condition:

Tighten the Belts: Ensure that the belts are properly tensioned. Loose belts can lead to inaccuracies in print dimensions and affect overall print quality. Refer to your printer’s manual or online resources for guidance on adjusting belt tension.

Inspect for Damage: Regularly check the belts for signs of wear, fraying, or damage. If you notice any issues, consider replacing the damaged belt promptly. A damaged belt can negatively impact print accuracy.

Clean the Belts: Dust and debris can accumulate on the belts over time. Use a soft brush or cloth to gently clean the belts. Avoid using any abrasive materials that could scratch or damage them.

Lubrication: Unlike some other printer components, 3D printer belts do not require lubrication. In fact, applying lubricant can attract dust and debris, leading to more problems. Keep the belts clean and dry.

Check Pulleys and Idlers: Inspect the pulleys and idler wheels that guide the belts. Make sure they are secure and rotate smoothly. Tighten any loose screws or nuts.

Avoid Overloading the Printer: Excessive stress on the belts due to heavy print loads can cause premature wear. Be mindful of the weight and size of the objects you print.

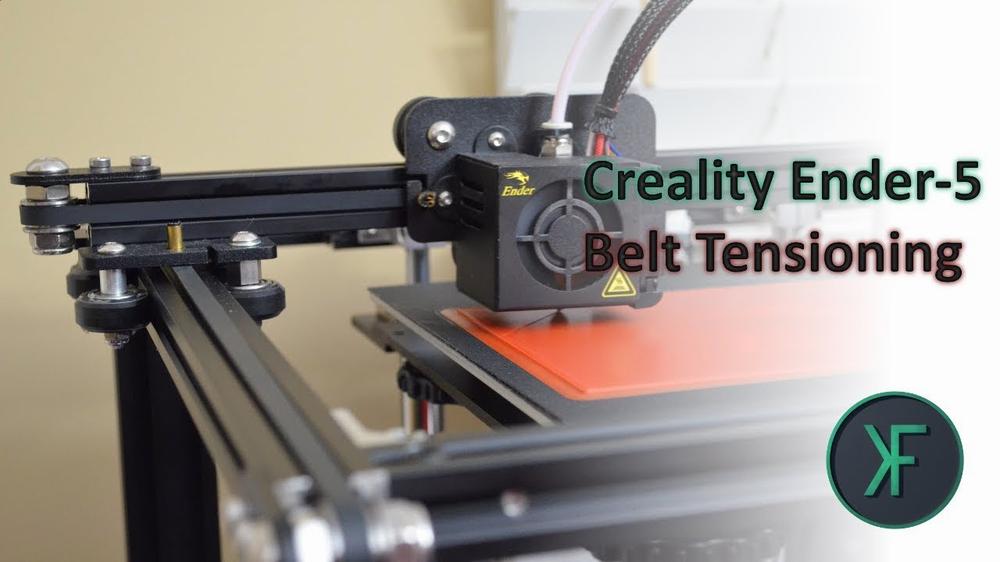

IMG Source: ytimg.com

Improving your Creality Ender 7 3D printer’s performance with upgraded belts is a great idea. Here are some steps and recommendations to enhance your printing experience:

Properly Tighten Your 3D Printer Belt:

Decrease Jerk, Acceleration, & Printing Speed:

Check for Loose Screws & Nuts:

Install a Cooling Fan or Heatsink:

Inspect Pulleys for Damage:

Ensure Correct Motor Driver Current:

Replace Damaged Belts or Bearings:

Additionally, consider exploring upgrades like the Triple Lead Screw Upgrade Kit, which enhances stability and smooth operation. This kit replaces the Z-linear motion system with linear bearings and rods, improving overall performance.

For more detailed instructions, you can refer to the Creality Ender 7 Service Tutorial Videos

IMG Source: media-amazon.com

Investing time and effort into your Creality Ender 7 belts will result in smoother printing experiences and long-term durability for your printer.