Are you looking to dive into the realm of 3D printing and explore the intricacies of the Creality CR-10 frame? Let’s unravel the key components and advantages that make the CR-10 a standout choice for enthusiasts and professionals alike. The sturdy aluminum frame, generous build volume, and heated bed are just a few features that set this printer apart.

Join us as we delve deeper into the world of 3D printing with the Creality CR-10.

The Creality CR-10 is a popular 3D printer known for its large build volume and reliable performance. Let’s delve into some details about the CR-10 frame:

Build Volume: The CR-10 offers an impressive build volume of 300x300x400mm. This generous space allows you to create sizable 3D prints without the need to split them into smaller parts.

Frame Material: The CR-10 features an aluminum frame, which provides stability and durability during printing. This robust construction ensures that your printer remains steady even during longer print jobs.

Heated Bed: The printer comes equipped with a heated bed, which is essential for preventing warping and ensuring good adhesion of the printed layers. A heated bed allows you to work with various filament types, including PLA, ABS, PETG, TPU, and more.

Filament Compatibility: The CR-10 accepts 1.75mm filament, making it compatible with a wide range of materials. Whether you’re experimenting with flexible TPU or creating functional parts with PETG, the CR-10 can handle it.

While the CR-10 is a solid printer out of the box, many enthusiasts choose to enhance its capabilities through upgrades. These upgrades can transform the printer into a more versatile machine, capable of handling different materials and improving overall print quality.

If you’re interested in exploring upgrades, consider checking out the frame support brace for the CR-10. It’s an awesome addition that provides extra stability and rigidity to the printer frame. You can find detailed instructions and files for the support braces on Thingiverse. Additionally, here are some other accessories and upgrades you might find useful:

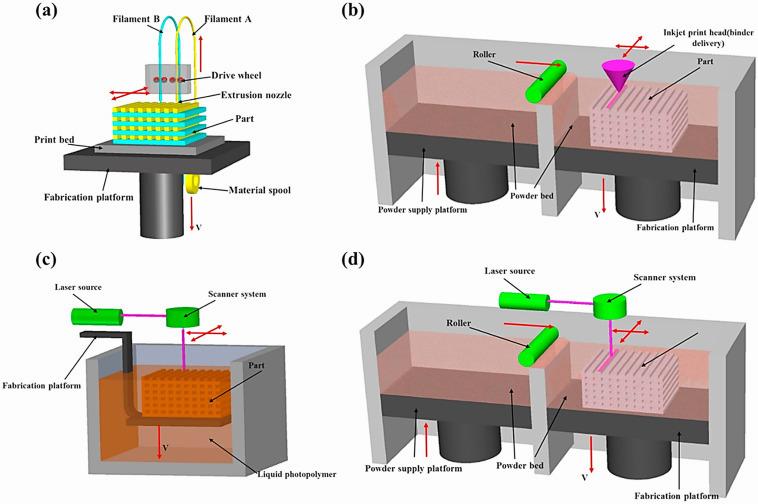

Durability and performance in 3D printing are influenced by the choice of frame materials. Let’s delve into this topic:

Traditional Durability Approaches:

3D-Printed Materials and Durability:

Factors Impacting Durability and Performance:

IMG Source: els-cdn.com

The frame of a 3D printer serves as its fundamental structural framework, akin to a skeleton. Here are the key advantages of having a sturdy 3D printer frame:

Reduced Vibrations: A robust and well-engineered frame minimizes vibrations. This stability ensures consistent movement of various parts along the printer’s axes, leading to better print quality and accuracy.

Enhanced Print Quality: A stronger and sturdier frame contributes to improved print quality. Especially when printing materials like ABS or larger parts, a solid frame helps maintain precise layer alignment and reduces distortions.

Noise Reduction: Enclosed frames tend to be quieter, reducing noise during printing. This is particularly beneficial if you prefer a quieter working environment.

Heat Retention: Sturdy frames can better retain heat within the printer, which is advantageous for materials like ABS that require consistent temperatures for successful printing.

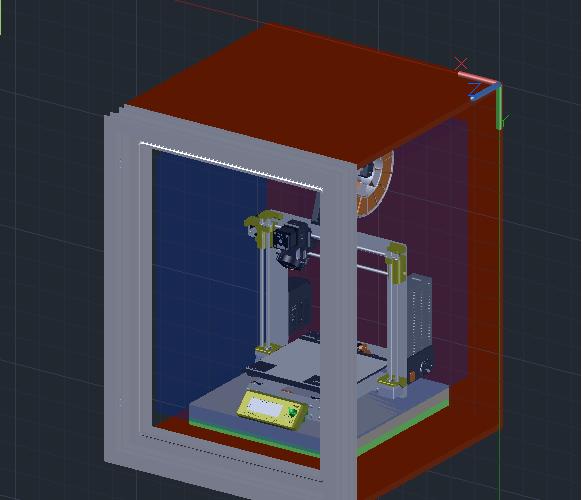

IMG Source: prusa3d.com

The Creality CR-10 SE is an entry-level 3D printer that falls into the “premium class.” It boasts impressive features, ease of use, and high-quality prints. Let’s delve into some aspects of the CR-10 SE, including its frame design and optimization options:

Frame Stability and Design:

Speed and Precision:

LED Light Bar:

First Layer Optimization:

Creality Print Slicer Compatibility:

In summary, the Creality CR-10 SE is an excellent choice for hobbyists and professionals alike. Its stability, speed, and user-friendly features make it a standout 3D printer in its class.

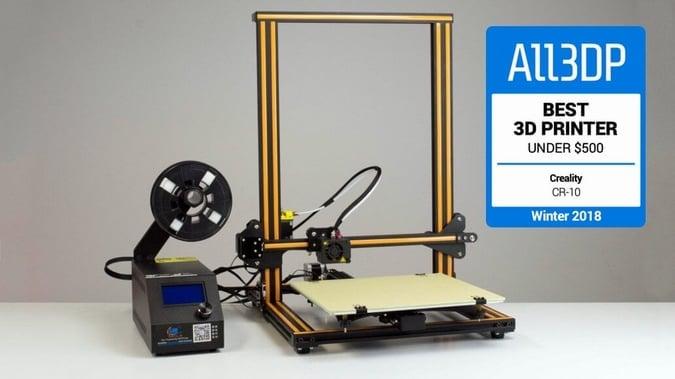

IMG Source: all3dp.com

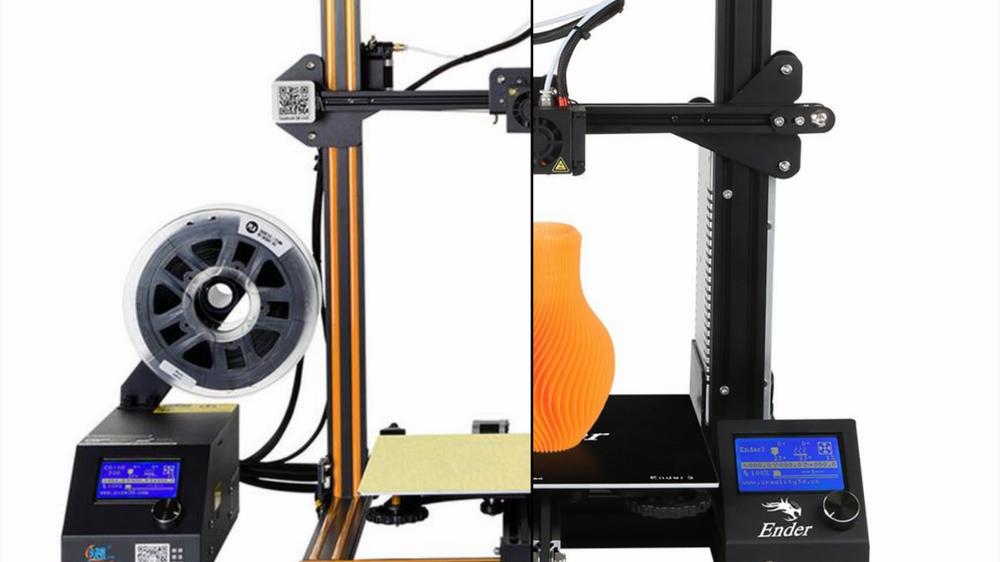

Let’s delve into the differences between the Creality CR-10 and frames of other 3D printers. Here are some notable comparisons:

Creality CR-10 vs. CR-10 V2 vs. CR-10 V3:

Bambu Lab A1 vs. Creality CR-10 Smart:

Creality CR-10 Smart Pro:

IMG Source: all3dp.com

As we wrap up our exploration of the Creality CR-10 frame, it’s evident that a robust frame is essential for achieving high-quality prints and operational stability in the 3D printing realm. The CR-10’s frame material, build volume, and compatibility with various filaments showcase its versatility and reliability. Whether you’re a hobbyist looking to enhance your printing experience or a professional aiming for precision and durability, the Creality CR-10 frame stands as a solid foundation for your creative endeavors.

Remember, a well-constructed frame is not just a supporting structure but a gateway to unleashing the full potential of your 3D printing projects.