Welcome to the world of 3D printing innovation with the Bambu Lab X1 Hotend! Dive into the cutting-edge features of this desktop 3D printer, from its Automatic Material System (AMS) to its CoreXY High Speed system. Let’s explore how the Bambu Lab X1 series sets a new standard in color versatility, precision, and efficiency.

The Bambu Lab X1 Series is a cutting-edge desktop 3D printer that combines innovation, color versatility, and advanced features. Let’s dive into the details:

Automatic Material System (AMS): Bambu Lab’s X1 brings color back into the 3D printing community. With its 16 colors and multi-material capabilities, it’s a true 3D Printing Maestro. The AMS allows you to print freely in multiple colors and materials, making your creations vibrant and expressive.

All-Metal Hotend: The X1 features an all-metal hotend with a 300°C hardened steel nozzle (50 HRC). This enables you to work with more demanding materials beyond standard PLA and PETG. Think PA-CF (super rigid but abrasive carbon fiber filament), PA Tough (self-lubricating but highly hydroscopic), and PA PC (highly temperature-resistant but prone to warping).

Micro Lidar: The Bambu Micro Lidar brings micrometer-level precision into 3D printing. It probes the nozzle height, calibrates flow, and scans the first layer, opening up endless possibilities for precise prints.

Dual Automated Bed Leveling: Say goodbye to uneven prints! The X1 utilizes two sets of independent sensors and an algorithm to measure the nozzle’s height relative to the bed. The lidar and analog force sensors crosscheck for an extra layer of redundancy in bed leveling.

AI-Inspected First Layer: No more waiting around for that crucial first layer. The lidar sensor checks your first layer, ensuring it’s just right. Plus, our AI keeps an eye out for spaghetti monsters (yes, really!) with a confidence level of 86%.

Snap-Away Supports: Removing supports has never been easier. The X1 can use snap-away support material or dissolvable filament, minimizing the pain of support removal.

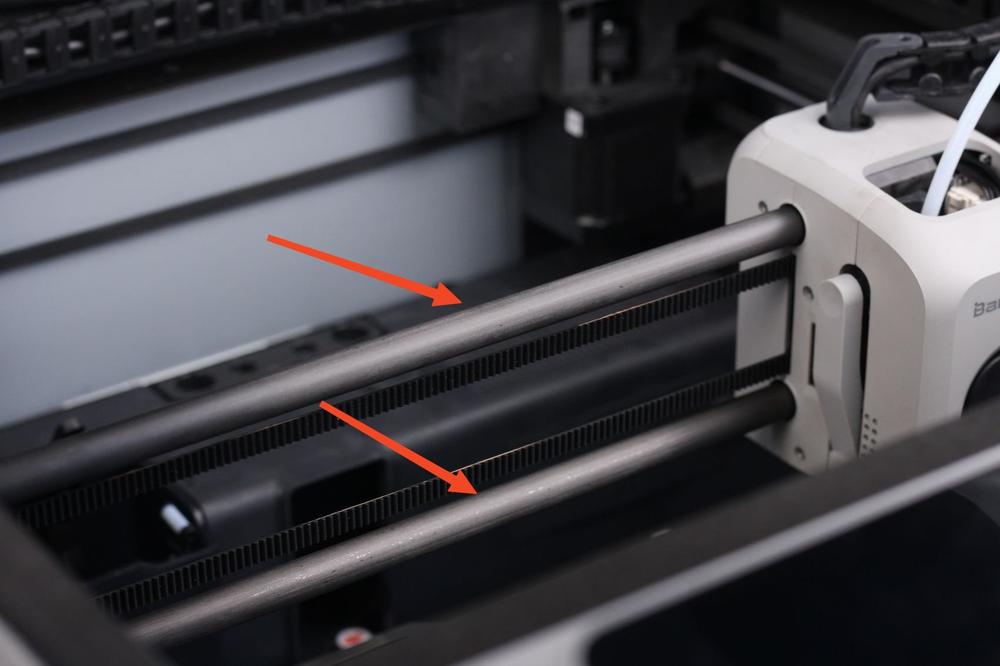

CoreXY High Speed: The X1’s CoreXY system ensures rapid and precise movement, making it suitable for both beginners and professionals.

Learn more about the Bambu Lab X1 Series on their official website.

Let’s compare the features of the Bambu Lab X1 Hotend across different models:

X1-Carbon:

P1S:

P1P:

IMG Source: redd.it

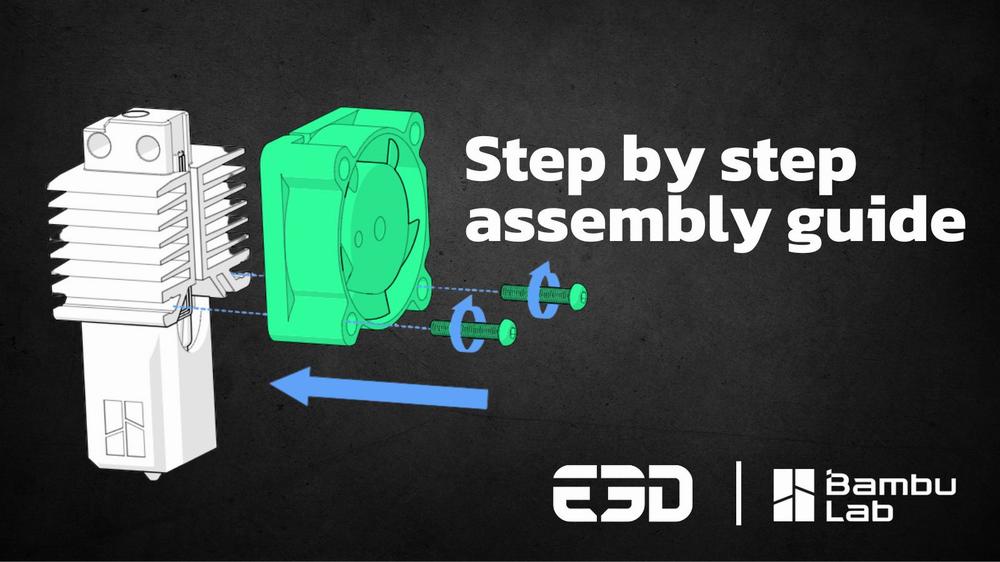

Here’s a concise guide for installing the Bambu Lab X1 Hotend:

For more detailed instructions, you can also refer to the following resources:

IMG Source: twimg.com

Here are some maintenance tips for the Bambu Lab X1 Hotend:

Regular Cleaning: Keep the hotend clean by removing any accumulated debris or filament residue. Use a soft brush or compressed air to clear any clogs.

Nozzle Replacement: Over time, nozzles can wear out or become clogged. Consider replacing the nozzle periodically to maintain optimal printing quality.

PTFE Tube Inspection: Check the PTFE (polytetrafluoroethylene) tube that guides filament into the hotend. If it’s damaged or worn, replace it promptly.

Heating Element and Thermistor: Ensure the heating element and thermistor are securely attached. If you notice any issues with temperature control, inspect and replace them if necessary.

PID Tuning: Perform PID tuning to optimize temperature stability. This helps prevent temperature fluctuations during printing.

Fan Maintenance: Clean or replace the cooling fan that cools the hotend. Proper cooling is essential for preventing heat creep and ensuring consistent extrusion.

Filament Quality: Use high-quality filament to avoid clogs and improve print results. Low-quality filament can leave residue and cause issues.

Calibration: Regularly calibrate your printer, including the hotend. Proper calibration ensures accurate extrusion and prevents under- or over-extrusion.

Check Wiring Connections: Inspect the wiring connections to the hotend. Loose or damaged wires can lead to printing problems.

Refer to Official Resources: Consult the official Bambu Lab documentation or community forums for specific maintenance instructions and troubleshooting tips.

For more detailed instructions, you can also refer to videos like this one on Bambu Lab Maintenance Steps.

IMG Source: bambulab.com

Let’s delve into user reviews for the Bambu Lab X1 Hotend. Here’s what some users have shared:

Enterprise Perspective:

For enterprise users, minimizing print failures over extended periods is crucial, and the chamber heating aids in achieving reliable results. The X1E’s price point is attractive, making it an accessible choice for businesses.

Build Space Considerations:

While the current setup can work with some workarounds, having dual extruders would significantly improve efficiency.

Overall Impressions:

IMG Source: bambulab.com

Embrace the future of 3D printing with Bambu Lab X1 Hotend and unlock a world of possibilities.