Welcome to the world of additive manufacturing with the Bambu Lab P1S 3D Printer. Today, we will explore the intricacies of one of its essential components: the Bambu Lab P1S Pulleys. These pulleys play a crucial role in maintaining tension and ensuring the smooth operation of your printer.

Let’s delve deeper into the functionality and maintenance of these vital parts.

The Bambu Lab P1S 3D Printer is a remarkable device that offers a seamless experience right out of the box. Here are some key features:

Now, let’s delve into the specific component you mentioned: the Idler Pulley. This pulley plays a crucial role in maintaining proper tension in the XY belt system. Here are the details:

Idler Pulley: The idler pulley is mounted on the XY belt tensioner—one on each side (XY). It contains two washers and an idler. You can find more information about its installation on the Bambu Lab Wiki.

Compatibility: The Idler Pulley is compatible with both the X1 Series and the P1 Series printers.

Specifications:

If you need to replace your idler pulley or want to explore other spare parts, you can check out the Bambu Lab Spare Parts Collection.

The Bambu Lab P1S 3D Printer boasts several impressive features that make it a reliable choice for 3D printing enthusiasts. Let’s delve into the details:

Easy Setup: The P1S is designed to be user-friendly, allowing you to set it up in just 15 minutes. No need to fuss around with complicated assembly instructions!

Well-Polished Hardware and Software: Bambu Lab has ensured that both the hardware and software components are finely tuned. This attention to detail contributes to a smoother printing experience.

Enclosed Body for High-Temperature Filament Printing: The P1S comes with an enclosed body, making it suitable for printing with high-temperature filaments. Whether you’re working with ABS or carbon fiber, this printer can handle it.

Up to 16-Color Printing with AMS: The P1S supports up to 16-color printing using Bambu Lab’s AMS system. This feature allows you to create vibrant and intricate multi-colored prints.

Impressive Acceleration: With an acceleration of up to 20,000 mm/s², the P1S can zip through your prints efficiently. In fact, it can even churn out a Benchy (a popular 3D printing benchmark) in just 18 minutes.

Built-In Camera for Monitoring and Timelapse: Keep an eye on your prints remotely using the P1S’s built-in camera. You can monitor progress and create captivating timelapse videos of your creations.

As for the Idler Pulley, it’s an essential component for maintaining proper tension in the XY belts. The package includes:

This idler pulley is compatible with both the X1 Series and P1 Series printers.

Additionally, the P1 Series printers come equipped with an all-metal hotend that supports long-time 3D printing filaments, including ABS and carbon fiber, at high temperatures. This ensures accurate and smooth extrusion for quality printing results.

In summary, the Bambu Lab P1S offers reliable out-of-the-box performance, making it a solid choice for 3D printing enthusiasts who value ease of use and versatility.

IMG Source: bambulab.com

The Bambu Lab P1S 3D printer has been making waves in the additive manufacturing (AM) industry, and for good reason. Let’s delve into its features and applications:

Ultra-Fast Printing Speeds: The P1S boasts mind-bogglingly fast print speeds, reaching up to 500 mm/s. This rapid printing capability makes it a valuable asset in industrial settings where efficiency is crucial.

Active Vibration Compensation: Bambu Lab has incorporated active vibration compensation technology into the P1S. This feature helps mitigate vibrations during printing, resulting in higher print quality and accuracy.

Multicolor Printing: The P1S comes equipped with an automatic material station (AMS), enabling multicolor printing. This versatility allows for creative and functional designs in various applications.

Reliable Kinematics and Motion Control: The P1S inherits the proven kinematics and motion control system from Bambu Lab’s flagship printer. This reliability ensures consistent performance in demanding industrial environments.

User Interface (UI): While the P1S excels in many areas, its UI is a notable drawback. The low-resolution, 2.8-inch monochrome LCD controlled by a directional pad may take some getting used to. However, once familiar, it remains workable.

In summary, the Bambu Lab P1S offers a compelling combination of speed, reliability, and multicolor capabilities, making it a valuable tool for industrial applications. Whether you’re prototyping, creating functional parts, or exploring intricate designs, the P1S has the versatility to meet your needs.

IMG Source: bambulab.com

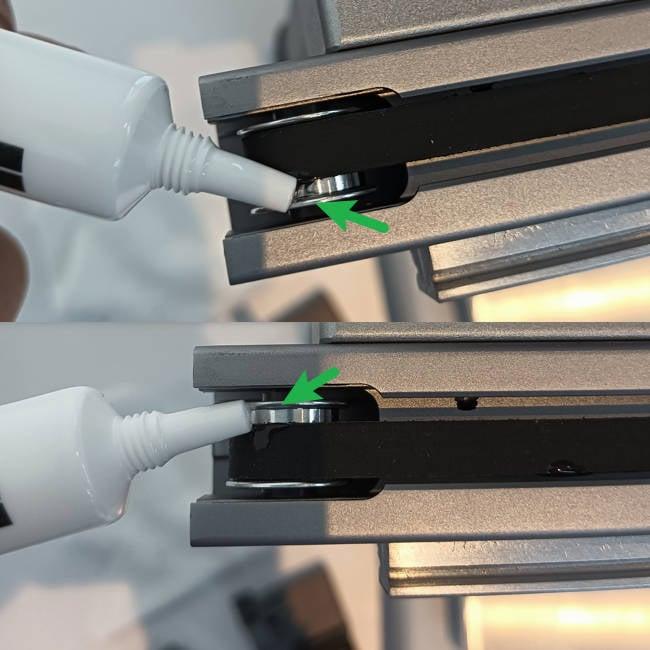

Proper maintenance is crucial to keep your Bambu Lab P1S 3D printer running smoothly and ensure high-quality prints. Here are some effective maintenance techniques for your P1S Pulleys:

Regular Cleaning and Lubrication:

Inspect and Tighten Components:

Keep the Printer Environment Clean:

Monitor Filament Usage:

Remember to follow the manufacturer’s guidelines from the Bambu Lab P1S user manual and the quick start manual

IMG Source: bambulab.com

The Bambu Lab P1S 3D printer offers several advantages, especially for industrial machinery and manufacturing applications. Let’s delve into the benefits of this impressive machine:

Blazing Speed: The P1S boasts Core XY speed, making it one of the fastest 3D printers available. With a remarkable acceleration speed of 20,000 mm/s², it can complete prints swiftly.

Enclosed Design for High-Temperature Printing: The fully enclosed structure allows for printing with high-temperature filaments like ABS and ASA. This feature is crucial for industrial applications where material durability and heat resistance are essential.

Precise Extrusion Control: The P1S features a motor directly connected to the extruder, resulting in better control over extrusion and retraction of flexible filaments. This precise and consistent extrusion ensures smooth and blur-free prints.

Auto Bed Leveling: The P1S incorporates one of the best auto bed leveling systems, ensuring a flat and even print surface for reliable results.

AMS (Automatic Multi-Material System) Compatibility**: The P1S is compatible with Bambu Lab’s AMS system, allowing for multi-color printing with up to 16 colors. This versatility is advantageous for creating complex and visually appealing industrial prototypes or end-use parts.

Quality Build Materials: With linear rods, a PEI-coated flex plate, and a self-cleaning tool head, the P1S delivers impressive print quality. It’s capable of achieving print speeds of up to 500 mm/s.

Here are the key specifications of the Bambu Lab P1S:

In summary, the Bambu Lab P1S strikes a balance between affordability, speed, and functionality, making it an excellent choice for industrial applications and beyond.

IMG Source: futurecdn.net

Invest in the care of your Bambu Lab P1S Pulleys today for smoother printing sessions tomorrow.