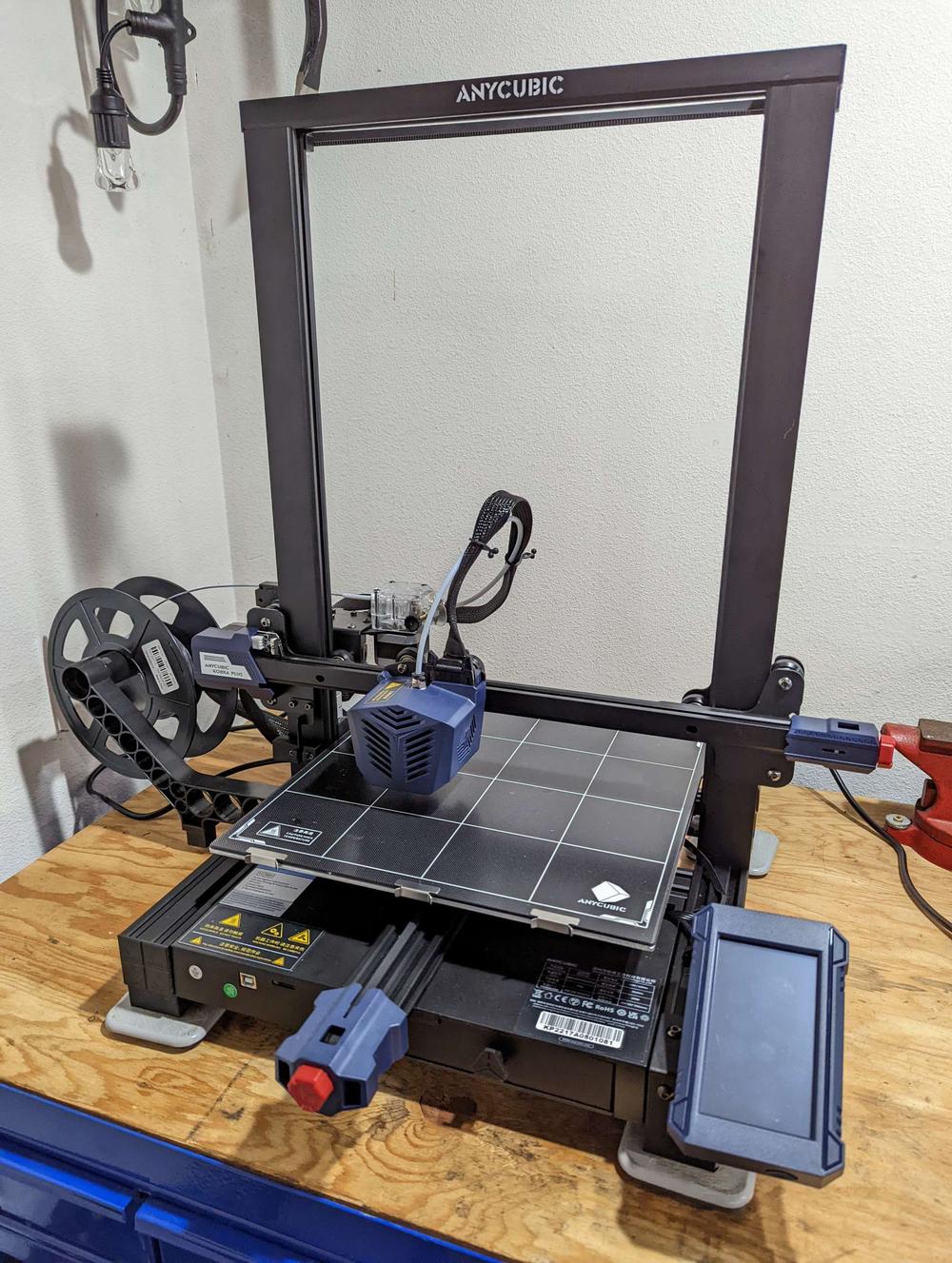

Welcome to the world of 3D printing with the Anycubic Kobra 2 Plus. Today, we’ll explore the intricacies of the Bowden Tube in this cutting-edge printer, revealing how it enhances your printing experience. Discover the crucial role the Bowden Tube plays in guiding filament for precise and efficient printing, setting the stage for seamless model creation and advanced printing capabilities.

The Anycubic Kobra 2 Plus is a large-format 3D printer with a print size of 320 x 320 x 400 mm, allowing you to create models of approximately 41 liters in volume in a single print. It features a Bowden extruder and a double-threaded z-axis moving structure, which enhances stability and enables high-speed printing while maintaining intricate model details.

Now, regarding the Bowden tube, if you need to check or replace it, here are some tips:

Inspect the Tube: First, examine the existing Bowden tube. Look for any signs of wear, kinks, or damage. If you notice any issues, it’s time for a replacement.

Replacement Process: While I don’t have a specific video for the Anycubic Kobra 2 Plus, the general process for replacing a Bowden tube is similar across various printers. Here’s what you can do:

Community Resources: You might find helpful discussions and videos on forums like Reddit. For instance, there’s a thread about tube replacement for the Anycubic Kobra, which could provide useful insights.

The Anycubic Kobra 2 Plus is the flagship 3D printer from Anycubic in 2023, designed to enhance your 3D printing experience with smart control and faster printing capabilities. Let’s delve into the specifics of the Bowden Tube compatibility and the benefits it offers:

Bowden Tube Compatibility:

Benefits of Bowden Tube:

In summary, the Bowden tube system in the Anycubic Kobra 2 Plus contributes to improved print quality, faster speeds, and versatility in filament choices. If you encounter any issues related to the Bowden tube, consider checking or replacing it following the manufacturer’s guidelines.

IMG Source: the-gadgeteer.com

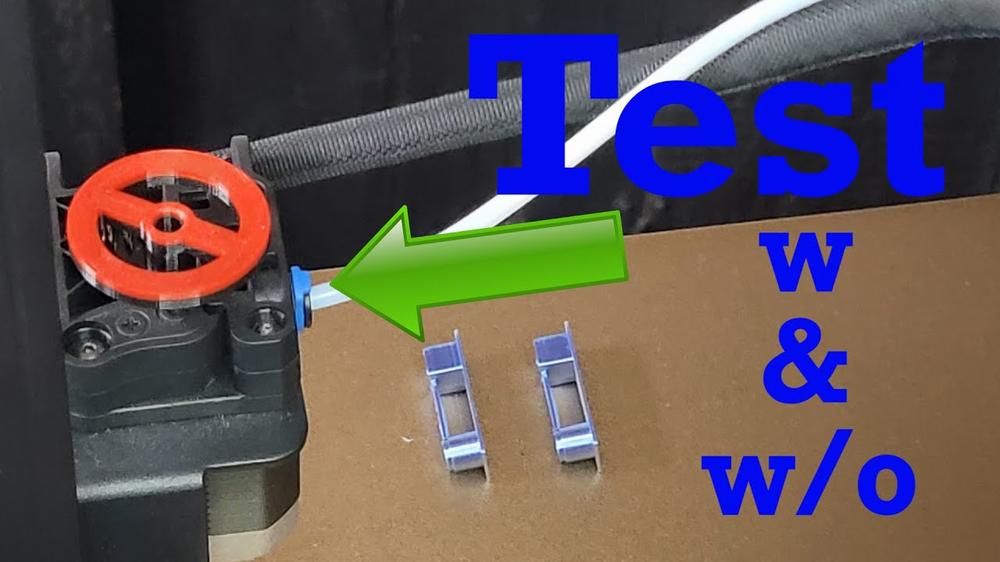

Let’s walk through the installation of the Bowden Tube for your Anycubic Kobra 2 Plus 3D printer. The Bowden tube is a critical component that guides filament from the extruder to the hotend. Here are the steps to install it:

Identify the Tube: First, locate the Bowden tube. It’s a short PTFE tube that guides filament into the hotend. You’ll find it near the extruder assembly.

Check for Damage: Inspect the existing tube. If it’s damaged or has come loose, you’ll need to replace it. Don’t worry; Anycubic Kobra printers usually come with a spare tube in a small ziplock bag.

Remove Filament: If the tube has come out while changing filaments, gently put it back in place. It’s not connected to anything; it just sits on top. Refer to this picture for clarification: .

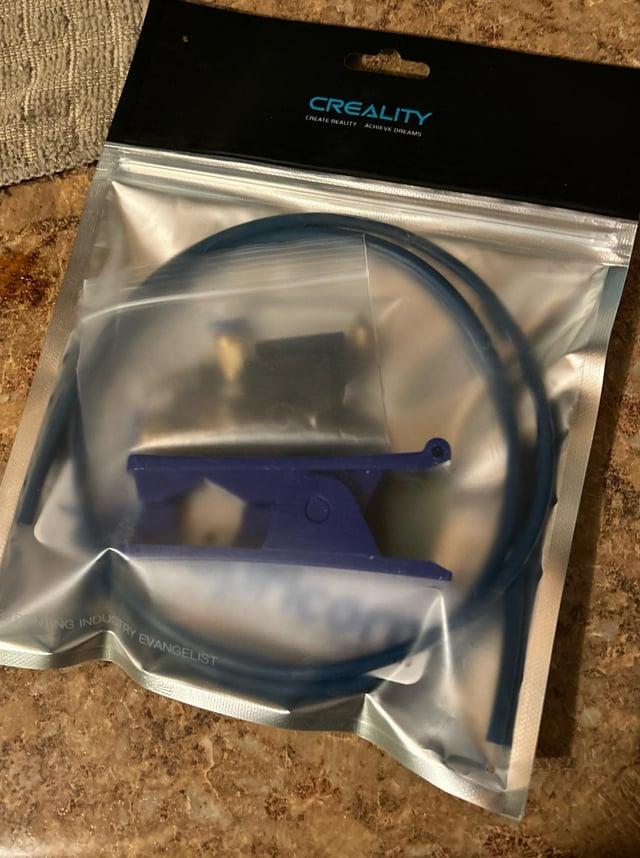

Replacement: If you need to replace the tube, consider getting a Capricorn tube. You can find these on Amazon. Alternatively, reach out to Anycubic customer support; they might direct you or even provide a replacement if you’re within warranty.

IMG Source: ytimg.com

The Anycubic Kobra 2 Plus is a high-speed 3D printer with a large build volume. Let’s delve into its features and capabilities:

Build Volume: The Kobra 2 Plus boasts an impressive build volume of 320 x 320 x 400mm (approximately 15.7 x 12.6 x 12.6 inches). This ample space allows you to create big models without compromising on size.

Print Speed: Anycubic claims that the Kobra 2 Plus is 10 times faster than traditional models. It can even print a 3Dbenchy (a popular benchmark model) in just 17 minutes. This speed is achieved despite sticking to the traditional “bed-slinger” design, where the print surface moves back and forth while the print head moves side to side and upwards.

Design: The Kobra 2 Plus features:

Quality and Filament: With the right filament, the Kobra 2 Plus delivers decent print quality. It uses standard 1.75mm filament, commonly PLA. You can even print large models by splitting them into smaller sections and assembling them using superglue.

Comparison with Other Models:

In summary, the Anycubic Kobra 2 Plus is a good-value 3D printer for those seeking a large build volume and faster printing times. While it has its shine, be aware of some issues with cloud printing and noisy fans. The price for the Kobra 2 Plus is $449.

IMG Source: all3dp.com

Troubleshooting issues with the Anycubic Kobra 2 Plus Bowden tube can be frustrating, but let’s tackle it step by step. Here are some suggestions to address the problem:

Filament Stuck in Bowden Tube:

If it’s too hard, unscrew the connector.

Alternative Approach:

Prevent Future Issues:

IMG Source: redd.it

Embrace the power of this innovative technology and elevate your printing experience to new heights.