Imagine a world where your 3D printer could alert you before running out of filament, saving you from failed prints and wasted time. The Anycubic Kobra 2 Max Filament Sensor brings this vision to life, offering a solution that enhances your printing experience. Discover how this innovative technology revolutionizes filament management for seamless and efficient printing.

The Anycubic Kobra 2 Max 3D printer comes equipped with a filament runout sensor. This sensor is an optional accessory for FDM (fused deposition modeling) 3D printers and is quite popular among users. Here’s what you need to know about it:

Functionality: The filament runout sensor automatically monitors the filament levels during printing. When it detects that the filament has run out or broken, it pauses the 3D printer’s operation. This feature helps prevent print failures due to filament depletion and ensures uninterrupted printing.

Purpose: By using the filament runout sensor, you can save filament and reduce the chances of failed prints. It’s especially useful for long prints or when you want to ensure a successful outcome without constantly checking the filament spool.

Installation: If you have an Anycubic Kobra Neo, you’ll need to purchase the filament runout sensor kit separately for an upgrade. However, some Anycubic FDM 3D printers, including the Kobra 2, come with the sensor pre-installed.

Hassle-Free Filament Management: With the sensor in place, you can focus on your designs and let the printer handle filament changes automatically. It’s a convenient feature that enhances the overall printing experience.

The Anycubic Kobra 2 Max 3D printer features a Filament Runout Sensor, which is a valuable technology for filament management. Let’s delve into the details:

Filament Runout Sensor:

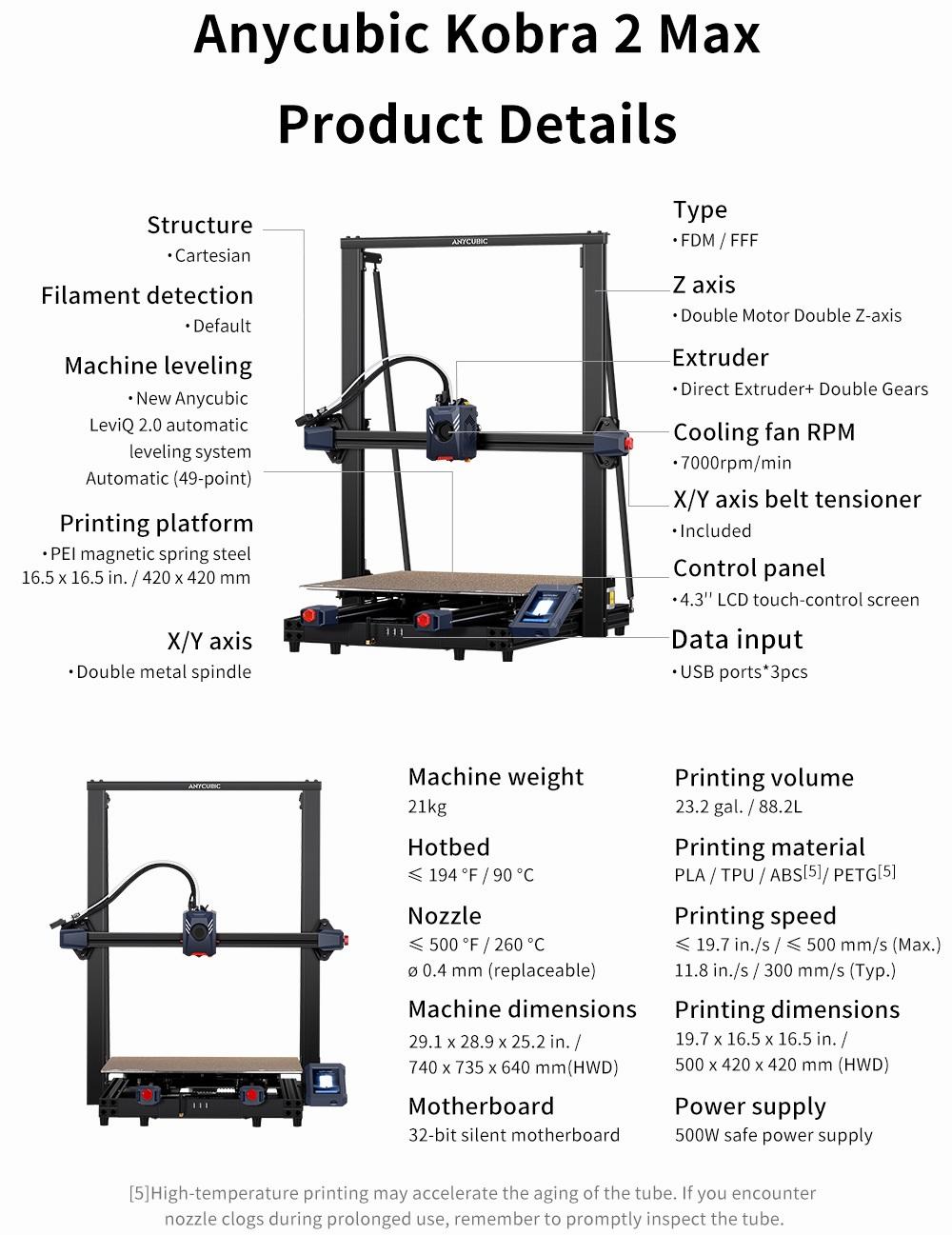

Additional Features of Anycubic Kobra 2 Max:

In summary, the Filament Runout Sensor

IMG Source: filament2print.com

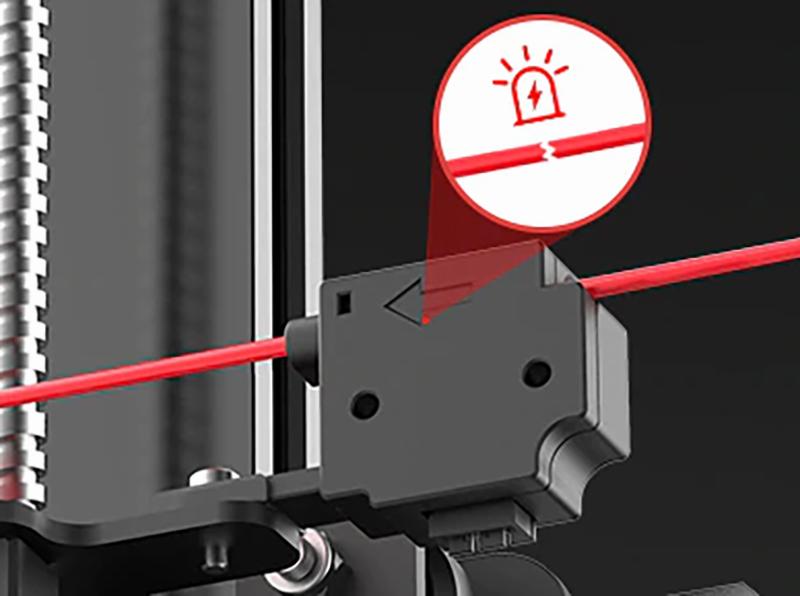

Let’s walk through the steps to install the filament runout sensor on your Anycubic Kobra 2 Max 3D printer. This sensor helps prevent printing failures due to filament depletion.

Gather the Necessary Tools and Components:

Prepare Your Printer:

Install the Filament Runout Sensor:

Calibration and Testing:

For more detailed instructions, you can refer to the official Anycubic tutorial on installing the filament runout sensor for the Kobra series.

IMG Source: anycubic.com

Let’s delve into the benefits of using a filament runout sensor in 3D printing. These sensors play a crucial role in enhancing the printing process. Here’s why they matter:

Avoiding Print Failures: Filament runout sensors detect when your printer runs out of filament. This feature is particularly valuable for large 3D prints. Imagine working on a massive project, only to realize midway that your filament spool is empty.

With a runout sensor, the printer pauses, allowing you to replace the filament and resume printing from where it left off.

Time and Material Savings: By preventing print failures due to filament depletion, you save both time and material. Wasted filament can be costly, especially for intricate or time-consuming prints. The sensor ensures that you don’t waste hours of printing effort.

Large Print Jobs: For printers with large build areas, filament runout sensors are essential. When printing objects that require more than one spool of filament, these sensors become invaluable. Whether it’s a massive sculpture, architectural model, or functional part, the sensor ensures uninterrupted printing even with multiple spools.

Cooling Down Safely: When a filament runout is detected, the printer moves the print head away from the object and allows everything to cool down. This prevents any damage to the partially printed layers. Once you load a new spool and thread the filament, you can continue printing seamlessly.

Affordable Options: You don’t need an expensive printer to enjoy this feature. Even budget-friendly printers like the Creality Sermoon D1 come equipped with filament runout sensors. So, whether you’re a hobbyist or a professional, consider a printer with this handy feature.

For more technical details, you can explore resources like FUTEK’s overview of sensors used in 3D printers.

IMG Source: circuitdigest.com

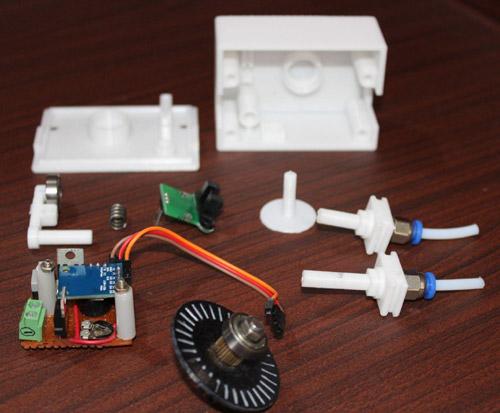

Let’s dive into the maintenance guide for the Anycubic Kobra 2 Max Filament Sensor. Proper maintenance ensures smooth printing and reliable performance. Here are the steps to install a filament runout sensor for your Kobra 2 Max:

Understanding Filament Runout Sensors:

Step 1: Gather Tools and Materials

Step 2: Locate the Filament Sensor Port

Step 3: Connect the Sensor

Step 4: Adjust Sensor Position

Step 5: Test the Sensor

Step 6: Calibration (if needed)

Step 7: Resume Printing

Regular Maintenance Tips:

For more detailed instructions and visual aids, you can refer to the official Anycubic Kobra 2 Max Filament Runout Sensor Installation Guide .

IMG Source: anycubic.com

Embrace the convenience and reliability of the Anycubic Kobra 2 Max Filament Sensor for a smoother and more efficient printing journey.