Are you looking to take your Creality K1 Max 3D printing experience to the next level with the FlowTech Hotend by Micro Swiss? In this detailed guide, we’ll explore the remarkable features of this cutting-edge hotend designed specifically for the Creality K1 and K1 Max. Say goodbye to nozzle leaks, complicated nozzle changes, and unreliable performance.

Let’s uncover how the FlowTech Hotend can revolutionize your printing process.

The FlowTech™ Hotend by Micro Swiss is a cutting-edge addition to the world of 3D printing. Specifically designed for the Creality K1 and K1 Max, this innovative hotend addresses common issues and simplifies the printing process. Let’s dive into the details:

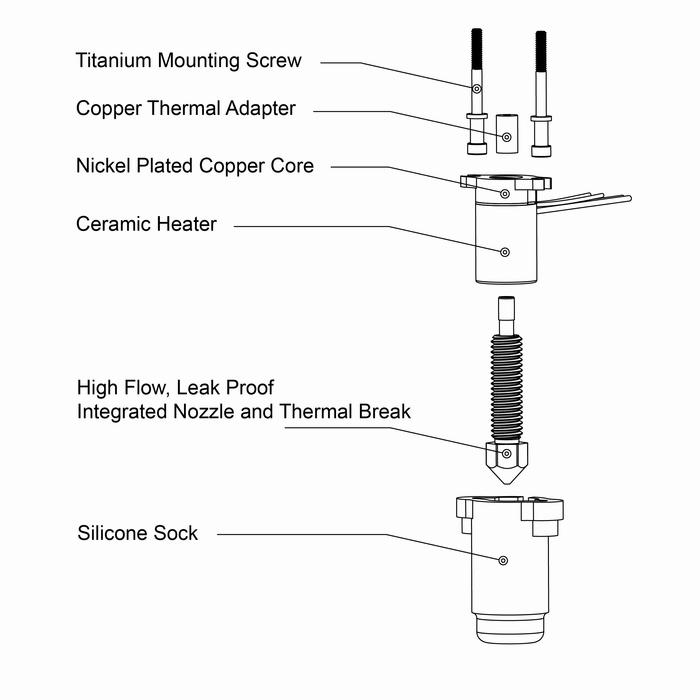

Leak-Proof Nozzle: Say goodbye to messy nozzle leaks that ruin your prints and waste filament. The FlowTech Hotend combines the nozzle and thermal break into one permanently sealed assembly, ensuring a leak-proof experience.

Effortless Nozzle Changes: Swapping out nozzles used to be time-consuming and potentially hazardous. With the FlowTech Hotend, nozzle changes are a breeze—no need for hot tightening, and you can do it with just one hand.

High-Flow Characteristics: The ceramic cylindrical heater and 28.6mm melt zone provide excellent volumetric flow rate. Whether you’re printing intricate details or large models, the FlowTech Hotend delivers.

All-Metal Design: Built to last! The FlowTech hotend features an all-metal design that can handle most modern 3D printing filaments. Quality control is performed at multiple stages during manufacturing, ensuring reliability.

300°C Max Temperature: This hotend is rated at 300°C temperature with a properly tuned NTC thermistor for each specific printer. No firmware changes are needed for the Creality K1 and K1 Max.

Installation is straightforward, and you’ll enjoy the benefits of this upgrade without compromising your printer’s existing specifications. Made in the USA by Micro Swiss, the FlowTech Hotend is a game-changer for 3D printing enthusiasts.

If you’re interested, you can find the FlowTech Hotend for Creality K1 / K1 Max on the Micro Swiss Online Store

The FlowTech™ Hotend for Creality K1 / K1 Max is a cutting-edge hotend developed by Micro Swiss. Let’s dive into its impressive features:

Leak-Proof Nozzle Assembly: Say goodbye to messy nozzle leaks that can ruin your prints and waste filament. The FlowTech Hotend integrates the nozzle and thermal break into a single permanently sealed assembly, ensuring a leak-proof hotend.

Easy, Cold Nozzle Change: Swapping out nozzles used to be a time-consuming and potentially hazardous task. With the FlowTech Hotend, nozzle changes are effortless, and there’s no need for hot tightening. You can do it with just one hand!

High-Flow Characteristics: The ceramic cylindrical heater and 28.6mm melt zone provide excellent volumetric flow rate, allowing for efficient extrusion.

All-Metal Design: Built to last! The FlowTech hotend features an all-metal design that can handle most modern 3D printing filaments. It’s machined and assembled in-house, with quality control checks at multiple stages during manufacturing.

Each hotend undergoes a full thermal cycling test before packaging.

300°C Max Temperature: This hotend is rated at a maximum temperature of 300°C. It comes with a properly tuned NTC thermistor for each specific printer. For the Creality K1 and K1 Max, no firmware changes are needed.

Remember, the FlowTech Hotend is designed as an easy drop-in upgrade

Made in the USA by Micro Swiss, the package includes:

IMG Source: creality3dofficial.com

If you’re seeking to enhance your Creality K1 Max‘s performance or replace a worn-out hotend, this step-by-step guide will navigate you through the Hotend Kit

Preparation:

Remove the Old Hotend:

Install the New Hotend:

Test and Fine-Tune:

Print a Calibration Object:

Final Checks:

For more detailed instructions, you can refer to the official Creality K1 Max Hotend Kit Replacement guide

IMG Source: micro-swiss.com

The Creality K1 Max is known for its speed and impressive print quality. Here are some recommendations to enhance your print quality:

Calibration: Start by recalibrating your printer. Check flow, pressure advance, and temperature settings. Ensure proper belt tension using the sound method.

Slicer Choice: While you’ve been using Orca slicer, consider experimenting with Creality’s own slicer. Some users report better quality with it compared to Orca or Prusa slicers.

Flow Test: Run a flow test to fine-tune extrusion. Adjust flow rate based on your results. Some users achieve excellent prints at 250mm/s using Orca slicer profiles.

Filament Choice: Try using high-speed filament (not necessarily Creality brand). High-speed filament tends to flow better and may improve print quality.

Speed: The K1 Max is capable of reaching speeds up to 600mm/s, but for optimal quality, consider reducing it to around 400mm/s.

Input Shaping: Note that the stock firmware might only have input shaping active for the X-axis. Rooting the printer could enable it for both axes.

IMG Source: micro-swiss.com

Here’s a guide for maintaining the hotend on your Creality K1 Max 3D printer:

Hotend Replacement:

Routine Maintenance:

Remember to consult the official Creality K1 Max User Manual for more detailed information on maintenance and troubleshooting

IMG Source: creality.com

Dive into the world of 3D printing with confidence, knowing that your hotend is in top-notch condition.